|

Maturity: Popcorns mature in 85-90 days in rainy season (kharif) and 95¬-100 days in winter season (rabi).

Since kernels are the economic product, harvest should necessarily be done on the attainment of physiological maturity,

which is evidenced by the formation of a black polyphenol layer at the base of the kernels. For optimum popping expansion

the popcorn should be dried to 14-15% grain moisture. The harvested and shelled popcorn is stored in moisture-proof sealed

containers.

Cultural Practices: Land preparation for popcorn is similar to that for field corn. The most common method

is to use two or three tandem diskings, although some heavy soil types will produce better tilth if ploughed. Disking or

field cultivating is then used for seedbed preparation. If needed, a spike-tooth harrow or other finishing tools can be

used with the last pass over the field to smooth the seedbed.

Soil Requirements: Any soil type suitable for normal corn, should produce a good popcorn crop. Soil pH should

be in the range of 6.0 to 6.8. Popcorn seeds germinate more slowly than dent corn, and the seedlings grow at slower rate.

Thus, medium to coarse textured soils, which warm slightly faster than fine-textured soils should improve germination,

emergence and seedling establishment. The popcorn root system is less extensive than that of normal corn. Therefore high

clay soils and/or poorly drained soils will weaken the roots, reduce yield, and increase lodging.

Fertility: Fertility requirements for popcorn are similar to normal corn. Nitrogen is to be applied at a

rate of 100-110 kg/ha. Nitrogen requirements are based on expected yield. In general the rate is 85 percent of the

requirement for an expected yield of normal corn in the same field. Any normal corn fertilizer programme adapted

to popcorn production should take into consideration popcorn's relatively poor standing ability. However, it must

be kept in mind that high nitrogen rates can cause lodging, especially when less than the recommended rate of

potash is used. As popcorn seedlings grow slower than normal corn, a starter dose is more important than subsequent

split doses. Other nutrients are supplied according to need as shown by soil test, similar to normal corn requirements.

Planting: Kharif popcorn can be planted from the last week of May to the first fortnight of July.

A soil temperature of 10-130C is necessary. Planting later than July 15 often results in a reduction of yield and

maximum popping expansion. Early planting permits the crop to mature and reach the desired harvesting moisture of

15-18 percent by early to mid-October. Rabi sowing preferably is completed in between October end and middle of

November so that the crop can establish itself before the onset of winter.

Seed Rate:Seed rates for popcorn is higher than for normal corn because of its smaller plant size and lower

yielding ability. Generally, consider 25 percent increase above the recommended normal corn plant densities for most

soils and cultural practices. Row widths of 75-95 cm are common. With irrigation facility the population should be from

50,000 to 67,000 plants per ha. A slightly lower population is used for dry land areas. Thus recommended seed rate for

common popcorn varieties in India is 12-14 kg/ha of land.

Irrigation: Irrigation of popcorn is the same as that for field corns. Some growers like to delay early

irrigation to stimulate better rooting of the developing plants. However, the value of this practice has not been

determined. Irrigation during pollen shed is not recommended. Irrigation, should continue until the black-layer has

formed in the developing kernel.

Intercultural operations: Intercultivation with tractor or bullock drawn cultivator is usually undertaken

once at knee high stage and if weed situation requires, it is followed by one or two cultivations. Mechanical cultivation

will depend upon herbicide effectiveness.

Weed Control: Most effective herbicide for weed control is application of Atrazine or Simazine @ 1 kg ai

per hectare. The predominant appli¬cation method is with planting or before emergence. This gives weed protection up

to 30-35 days after sowing.

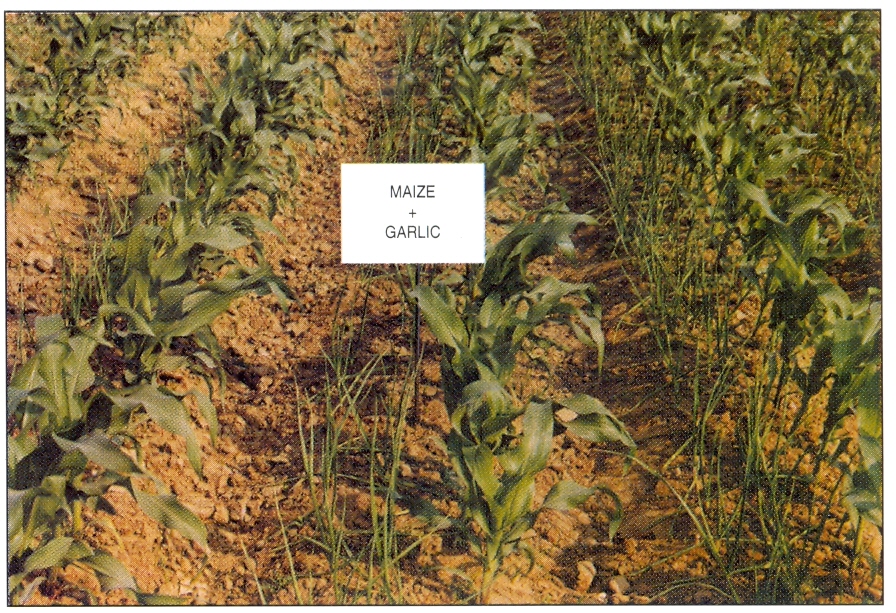

Intercropping: Popcorn being a highly remunerative crop can successfully be cultivated in periurban

agriculture. However, instead of cultivating popcorn as sole crop it may be intercropped with other highly remunerative

crops like cabbage, cauliflower, radish, spinach, coriander, potato, marigold, garlic, tuberose, gladiolus, spices, pea

etc. This provides additional income to the farmers from unit area and makes agriculture more sustainable.

Insect and Disease Control: Most, if not all, of the insects that attack field corn can also attack popcorn.

Insect control during the season is important, especially for Stalk borers viz., Chilo partellus Swinhoe in kharif (rainy)

season and Sesamia inferens Walker in rabi (post-rainy or winter) season. Spray of Endosulphan @ 2ml/1 within 21 days

after sowing is recommended.

Popcorn is more susceptible than field corn to diseases especially stalkrots and ear rots and blue eye disease caused

by three types of molds Penicillium viridicatum, P. cyclopium and Aspergillus glaucus. These pathogens not only affect

the crop in the field but may affect stored grains leading to low popping volume, low germination and sometimes a low

level of toxicity. This disease is best controlled by proper aeration during storage. However, application of Bavistin

@ 1 g ai per litre takes care of most of the foliar diseases.

|

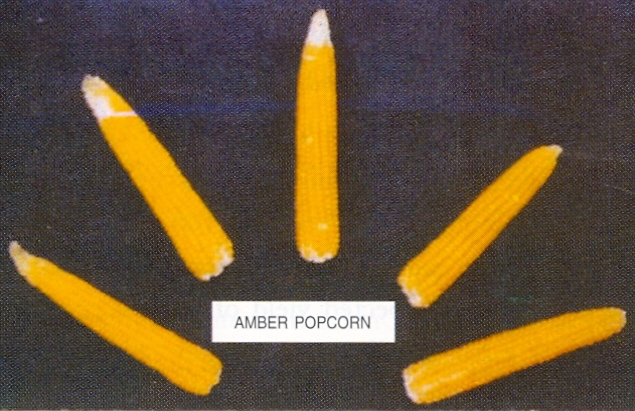

Popcorn intercropping with garlic in periurban agriculture

Popcorn intercropping with garlic in periurban agriculture