|

Pest and Disease Management:

A preventive spray of Endosulfan 35EC @2m1/1 of water is given to 10-14 days old plants to take care of stalk borers

Chilo partellus in kharif and Sesamia inferens in rabi. Sweet corn must be free of

insect larvae or worms for shipping or distant markets. The corn ear worm, Helicoverpa armigera is by far the

most difficult insect to control in sweet corn. Eggs are laid on the young silks where they hatch and the larvae feed

on the silks and tips of the ears. It is advised to direct the spray at the ear zone. When tassel shoots appear,

spray insecticide, then consecutive applications should be made depending on the situation.

Disease problems tend to be sporadic. Troublesome diseases include leaf blight and post-flowering stalk rots.

Use crop rotation, and avoid sequential planting in adjacent fields to minimize disease. A spray with Bavistin

@1 g/litre takes care of foliar diseases.

Harvesting of Cobs:

Plant growth picks up after the knee high stage rapidly as this is the grand growth stage.

About 45 days after emergence, the tassel emerges and 2-3 days later the silks emerge. Top dressing with urea is done

at tassel emergence. Sweet corn is an abundant pollen producer and seed set is usually very high. There should

be no moisture stress at tasseling-silking stage as moisture stress reduces seed set and in extreme cases barren ears

are also seen. As an ear approaches maturity, sugar changes to starch, the hull becomes tougher, and the kernels

pass through stages called pre-milk, milk, early dough, and dough. At field temperatures of 16°C, an ear may remain

in prime condition for as long as 5 days, while at 30°C it might remain in prime condition for only 1-2 days.

Corn will be ready for harvest approximately 18-22 days after completion of pollination

(indicated by drying of silk). As the field nears maturity, a few ears should be examined daily to determine the time

for the first picking. Corn is ready for harvest when the ear is full size for the variety, has a tight husk,

and has somewhat dried silks. The kernels are fully developed and exude a milky liquid when punctured.

Delaying the harvest will progressively reduce the sugar content in the kernels. The ear husks are still green

at this stage and the kernels remain lustrous at milky stage. Whether harvested by hand or machine, sweet corn

should be collected at night or early in the morning, when the environment remains cool. Every effort should be made

to keep harvested ears cool and in shaded areas. Ears can be eaten raw, as a dessert or ears can even be steam boiled,

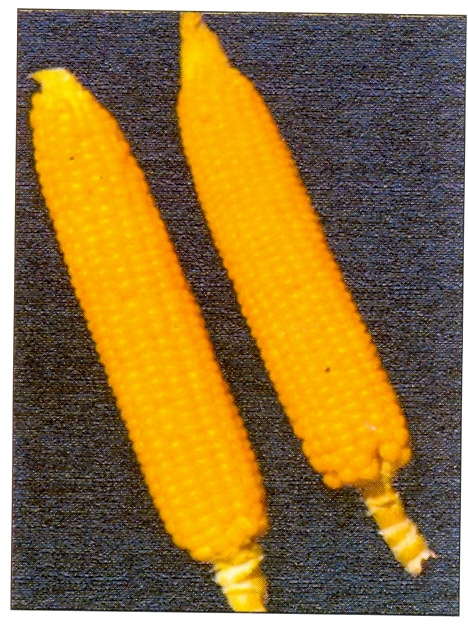

salted and eaten, which is more relishing. Under good management, two ears are borne per plant especially in the

rabi (winter) season. Staggered planting of sweet corn at intervals of 7-10 days will enable farmers

to harvest sweet corn ears at intervals for continuous supply to the market and thereby get continuous and higher returns.

Harvesting of Green Fodder:

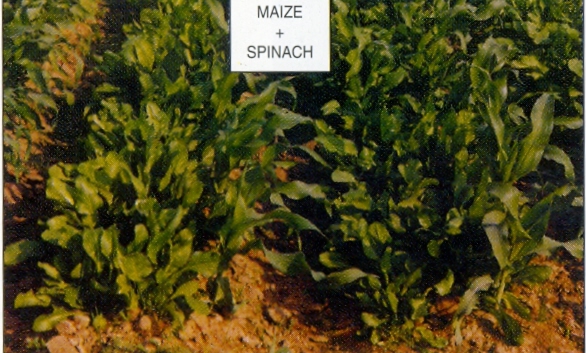

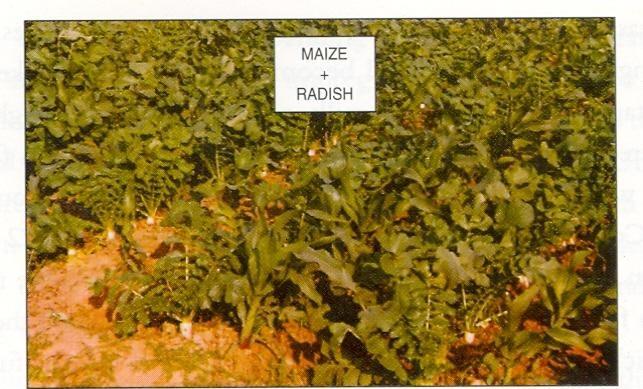

In addition to high market value for sweet corn one additional advantage is that immediately after harvest of green cobs,

the plants remain green and can readily be used as fodder. It is estimated that up to 250-400 q/ha fodder may be

harvested from one crop, which provides additional income to the farmers.

Post-harvest Handling:

Because sweet corn has a high respiration rate, it produces heat which can cause ears in bulk trailer loads to heat up

considerably during delays between picking and precooling. The longer the delay, the greater the heating, conversion

of sugar to starch, and subsequent quality loss. Sweet corn must be moved quickly from the field to packing sheds,

where it should be rapidly sorted, packed, and cooled. Sweet corn is generally packed in wire bound wooden crates,

which can hold from 4 to 6 dozen ears, depending on the size of the crate or ears. However, cabbage bags or wax

impregnated cartons can be used and typically hold about 60 ears. The ears are graded according to the raw ear size

and packed in polythene bags and sold in the market. Under room temperatures sweet corn will lose 50% or more of

its sugars in 24 hours. Sweet corn should be precooled to as close to 0oC as possible, although it is rarely

cooled below 4oC in commercial practice. Several methods of cooling sweet corn are available:

Hydro-cooling: It consists of precooling by either showering the corn or immersing it in cold water.

It is the most popular method of precooling. Immersing the corn in cold water is much more efficient than showering

the corn. A dealer or engineer is to be consulted to ensure maximum efficiency and sufficient capacity to handle

anticipated daily volume of sweet corn.

Packaging: This is an excellent method of precooling sweet corn which is used for local, direct shipments.

In this method, 7-10 Kg of crushed ice is distributed throughout the container (box or crate) during the packaging

process. The amount of ice needed in a package depends on the temperatures of the corn at the time of packing and on

the expected length of the marketing period. Typically about 500 g of ice for 2 Kg of sweet corn is sufficient.

The main disadvantage is that if shipment to market is delayed, the package is heavy and wet.

Cold Storage: To maintain best quality, sweet corn is placed in cold storage immediately after precooling.

Storage can be in a refrigerated truck or in a room. Temperature is maintained as close to 0oC as possible

without freezing the corn, and relative humidity of the air in the cold room at 95 percent or higher to keep

the corn fresh. The corn is to be taken out as soon as possible since more than a few days in cold storage will

decrease quality.

Cooling in Transit: Sweet corn must also be kept cold in transit. The best method consists of blowing finely

crushed ice over the top and through the corn crates, as the trucks are loaded. This method of icing keeps temperatures

low during transit but provides little or no additional cooling. The refrigerated truck only maintains the temperature

of the already cooled corn. It is not meant to be used as a substitute for precooling. It is important to remember

that for maximum quality and value, sweet corn must be continuously and properly refrigerated from harvest

until it reaches the consumer.

Obtaining Earliness: Several methods can be employed to obtain an early harvest of sweet corn.

The most obvious method is to choose a variety which is early to mature. Also, a more vigorous variety will

germinate under less-favourable growing conditions. In addition, seeds can be sown 10 to 20 days earlier using

clear plastic mulch. Photo-degradable mulch (30-day type is recommended; the plastic breaks down slowly after

exposure to sunlight) can be used to eliminate the cost of removing mulch at the end of the growing season.

It is recommended to apply herbicide and then cover with clear plastic. The plastic is left over the emerged plants

approximately 30 days, then cut and removed. Growing corn on black plastic mulch can also enhance earliness

and weed control.

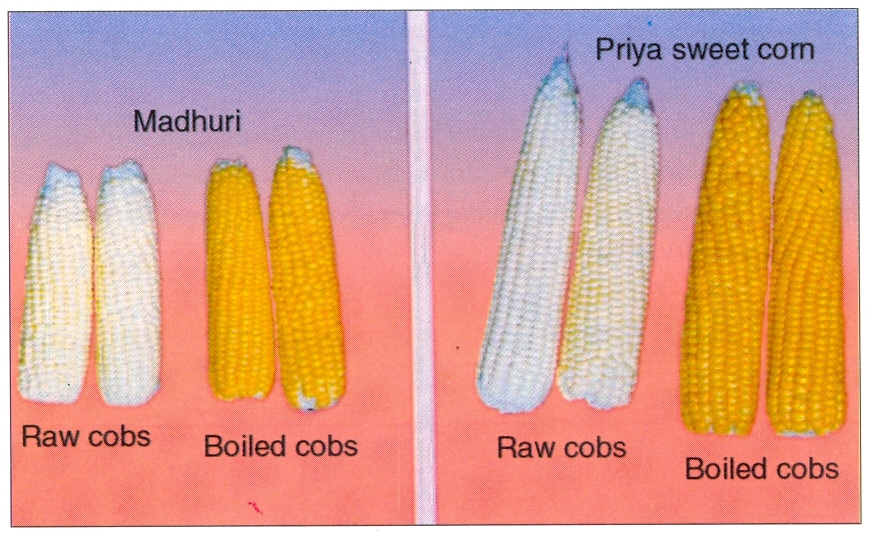

Corn Colour: Sweet corn comes in three colors: yellow, white and bicolour (yellow and white).

Cross-pollination of yellow kernel varieties with white kernel varieties will result in production of bicolour corn.

Also, if a bicolour is cross pollinated with a yellow variety, kernel colour will be predominantly yellow.

Although there are geographical preferences for certain kernel colors, there is no relationship between

colour and sweetness of sweet corn.

Yields: If water requirements are met and other cultural practices optimized, sweet corn yields

about 66000 ears per ha. High density planting can give higher number of harvested ears.

Pollination: Unlike most vegetables, corn is wind pollinated and must be planted in blocks.

Sweet corn of any type downwind from popcorn or field corn develops starchy kernels. Ears of supersweet sh-2

corn pollinated by a normal (su) sweet corn cultivar or a cultivar with the se gene will develop hard,

ugly and starchy dent kernels. To avoid this cross¬pollination, different kernel types must be separated

by at least 250 m or staggered planted so that they flower at least 14 days apart.

Precautions with Modified Endosperm Sweet Corn to Avoid Xenia:

Isolation of "sweet corn" cultivar plantings of different genetic types is necessary to prevent cross-pollination.

Xenia is the immediate effect of foreign pollen on a variety; on sweet corn (su), it will produce a starchy

kernel. Isolation can be obtained by planting at a different time, planting cultivars of different maturities,

or providing barriers and border rows. All of these methods will reduce the isolation distances necessary.

On a practical basis, commercial growers should provide at least 50 m separation, plant upwind of normal field corn,

and use four or more border rows.

|