B

utton mushroom cultivation has two major components, composting

(preparation of substrate/compost), and the crop management, (raising of

mushroom crop). The substrate preparation has undergone scores of

innovations/improvements suiting environment protection laws in many developed

countries. At the same time, casing medium has also been standardized with use

of peat and its alternative materials (FYM, Spent Mushroom Compost and Coir

Pith) with prime objective to improve productivity and quality of mushrooms.

Similarly, the crop management techniques have also been improved upon to

harvest highest possible mushroom yield over a shortest period of time. All the

operations/applications done after completion of composting are handled under

the head crop management. These include:

A. Agronomic crop management

B. Environmental crop management

A. Agronomic Crop Management

Agronomic crop management deals with the compost quantity to be

filled per m2 bed area, moisture content of compost, spawning method employed,

compost thickness in a bed or bag, casing application and thickness, watering

regimes employed, harvesting of crop and after care, pest management, hygiene

maintenance and so on. However, more important among these are

1. Spawning and spawn run

2. Casing materials, casing treatments, casing application, case

run and pinhead formation

1. Spawning and spawn run

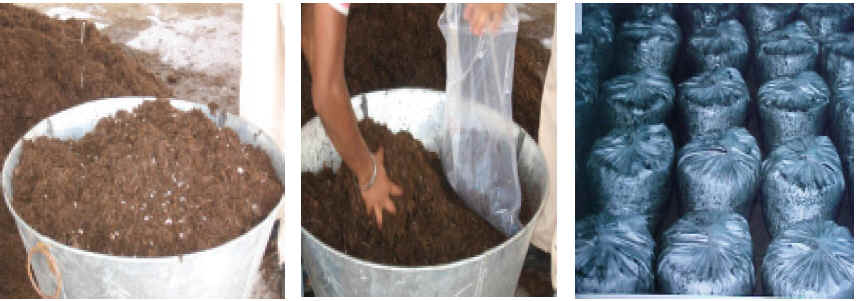

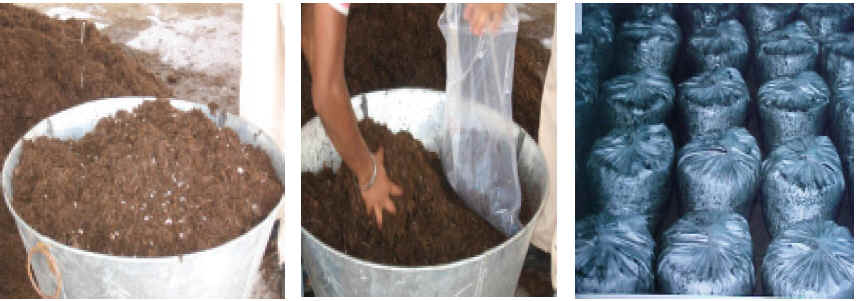

The steps involved are (Fig. 9.1)

● Good

quality compost with temperature of 25°C

● Mixing

of grain based spawn (@ 0.5-0.7% of wet compost weight) of A.bisporus under clean conditions (i.e. with clean hands and pre-sterilized

area)

● Filling

of spawned compost into polythene bags (12-15'’ depth) or beds (6-8'’ depth)

● Little

compressing and levelling of spawned compost

Fig. 1. Process

of spawning and filling in bags for white button mushroom

Loosely closing the mouth of polythene bags filled with spawned

compost (Covering with a clean newspaper / plastic sheet if filled in

trays/shelves)

● Shifting

the compost filled bags in cropping rooms with a temperature of 23 ± 1°C (air temp.), RH of 95% and high CO2 conc. (1.0-1.5% strain

dependent), and keeping the bags under above conditions for 12-14 days

● Completion

of spawn run (change of dark brown compost mass in to light brown colour)

Precautions

● Use

of fresh pure culture spawn

● Spawning

under clean conditions (preferably under positive pressure created using bacterial filters before inlet fans and air curtains at

doors)

● Proper

treatment of spawning area and tools with formalin, and cleaning of hands with dettol

● Maintaining

good hygienic conditions during spawning by keeping all the doors/windows closed

2. Casing and case run

Casing is a 3-4 cm thick layer of soil applied on top of spawn

run compost and is a pre-requisite for fructification in A. bisporus.

a. Casing materials

Earlier sub-soil material or organic matter rich soils were used

as casing in button mushroom cultivation. Presently peat is the most desirable

casing material used world wide with excellent mushroom yields and superior fruit body

quality. However, pest is not available in India. The other alternative recommended materials

are,

● Well

decomposed Farm Yard Manure (FYM) preferably two years old

● Well

decomposed Spent Mushroom Compost (SMC) (two years old anaerobically decomposed)

● Composted

coir pith (coir industry waste) (well decomposed & water leached)

● 1:1,

2:1 and 1:2, v/v of well decomposed FYM and SMC

● 1:1,

v/v of decomposed FYM or SMC with composted coir pith

● Decomposed

powdered bark of some forest trees

● Paper

industry waste

● Burnt

rice husk is also in use along with decomposed FYM (2:1, v/v) in seasonal

cultivation of button mushroom in Hayrana and Punjab with

reasonable success

b. Quality of casing materials

● Soft

texture

● Light

weight

● High

water holding capacity

● High

porosity

● Deficient

in available form of C and N

● Neutral

pH (7.0 – 7.5)

● Low

conductivity (400-600 μ moh)

c. Casing treatment

Casing material should be treated properly before its

application on the spawn run compost and the steps involved are:

● Make

a heap of casing material

● Wet

it up to 50-60% water holding capacity

● Fill

in trays and shift them to pasteurization chamber

● Steam

pasteurization at 60-65°C for 6-8 hours

● Auto-Cooling

Alternatively,

● Make

a heap of casing material on a cemented platform

● Wet

it up to 50-60% water holding capacity

● Drench

the wet casing with formalin @ 1 litre/m3 (40% formaldehyde) by mixing with shovel

● Cover

it with polythene sheet and seal the outer periphery thereafter by pouring sand/soil on outside margin

● Keep

the material for 24-48 hours in sun for fumigation effect

● Remove

the cover after 48 h and expose the material to open air and sunlight by spreading over with clean tools and permitting the formalin

fumes to escape in to air for 2-3 days before it is used as casing (formalin

treatment effect decreases at low temperature due to inadequate fumigation)

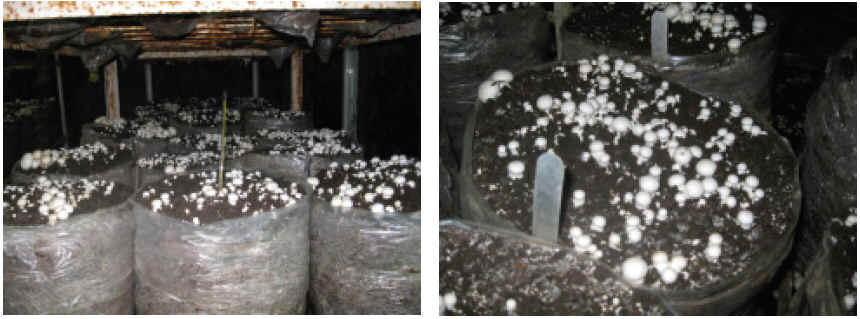

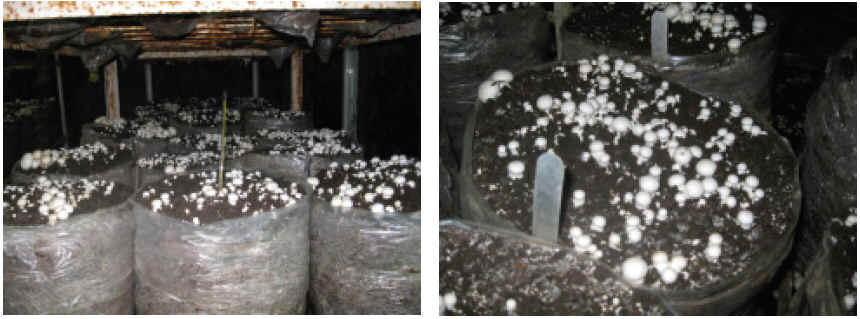

d. Casing application (Fig.

9.2)

● Unfold

the fully spawn run bag and make the top surface even by gentle pressing with hands

● Light

spray of water on spawn run compost

● Application

of 4-5 cm thick layer of casing uniformly using iron rings of 4 cm height or wooden blocks

● Water sparay

in installments immediately after casing application

Fig. 2. Process of

casing soil application for button mushroom cultivation

Precautions

● Casing

material should not be sieved but used as such with clumps, which permits more air spaces in casing

● Top

casing surface should have small mounts and valleys

● Care

should be taken to prevent re-infection of the casing materials

● Store

casing material in a sterilized /clean room before use in polythene bags or synthetic cloth bags

● Apply

water to casing in a few installments so that water does not run into spawn run compost

e. Case run and pinhead formation

Case run is done at a temperature of 24 ± 1°C, RH-95% and CO2

> 7500 ppm (strain dependent) for about one week. There is no requirement for fresh

air introduction during case run. It is considered complete when mycelia come in the

valleys of casing layer. After case run, the environmental conditions are changed by

bringing down the temperature to 15-17°C (air), RH to 85% and CO2 to 800-1000 ppm (strain

dependent) by opening of the fresh air ventillation and exhausting CO2. This change in

environmental parameters induces pinhead formation in 3-4 days (strain dependent) time.

The pinheads develop into solid button sized mushrooms in another 3-4 days (Fig.3). At this stage, the air inside the cropping room is changed 4-6 times in an hour to

maintain appropriate CO2 conc. as CO2 production is at its peak during first flush (actually peaks at

case run).

Fig. 3. Arrangement

of bags in cropping room and mushroom at button stage of development

3. Supplementation

Supplementation with protein rich supplements such as cotton

seed meal, soybean meal, alfa-alfa meal, feather meal, etc. has been found to

increase the mushroom yield. Supplementation can either be done at spawning or after spawn

run before casing. The later is more useful. Supplement is first grounded coarsely and

denatured by treating with 5000 ppm formalin and before its mixing in compost. The

practice normally increases the temperature of compost by 4-5°C and if done at the time of

spawning or in poor quality compost, it results in killing of mushroom mycelium or increased

incidence of moulds. If these problems are overcome supplementation can give 20-25%

enhanced yield. Supplementation at casing in spawn run compost also helps in

early and higher mushroom yield.

4. Ruffling

Ruffling of compost on completion of spawn run is done just

before casing. This practice is particularly useful for round the year cropping when

5-6 crops are taken per year and cropping period is reduced to about 4 weeks, as this

practice helps in exhaustion of compost earlier than normal. Ruffling of casing after a 3-4

days or so after casing is done by some growers to get uniform pinning.

5. Watering

Mushroom contains nearly 90% water and that gives us an idea how

water is important for the crop. Mycelium gets water from compost during spawn run

and compost + casing during case run and from casing during fruit body formation.

Water level in casing is maintained in 2 ways. One way is by its regular spray when

pinheads are pea sized and then by maintaining RH at 80-85% during cropping. If one of the

factors, (water spraying and RH) during cropping is disturbed, it will affect crop

productivity. Low RH during cropping will result in drying of beds, lightweight mushrooms,

discoloration of mushrooms and crop losses. Drying of casing will seal the casing medium

resulting in mat formation, which becomes impervious to water, and results in tremendous

crop losses. Water has to be replenished in casing to accommodate the water losses from

casing due to mushroom growth and evaporation. Lesser the water loss to room

air, better it is. Bed moisture and RH are although two different factors, but are

interdependent. Water spraying on mushroom beds at pin breaks should be avoided. The casing

should be wet enough when fresh air is brought in and room temperature lowered. The

wetness should be sustained till pin heads become pea sized, and that is the stage

when bed will require additional watering to allow pea-sized pins to develop into

button sized mushrooms. Watering to beds requires monitoring at each stage. RH in the

cropping room is monitored by using dry & wet bulb thermometers. Two ordinary stem

thermometers are put in the cropping room, placing one in the casing/compost bed and one

hanging in the air nearby (few cm apart). Bed temperature is 1-2°C higher than air

temperature. Computer control of AHU ensures application of cropping parameters with precision

during spawn run, case run and cropping. The water used for irrigation (spraying)

on mushroom beds should be clean, neutral in pH and free from salts, heavy metals

and other impurities. Water good enough for drinking/watering for vegetables/field

crops is also good for mushroom cultivation. It is desirable to test the quality of

water before the mushroom growing is started at a particular site.

6. Harvesting and after care

Mushrooms with 4-5 cm dia., with hard pileus and closed veil are

ready for the harvest. Mushrooms are harvested by holding them between

forefinger and thumb, and rotating in clockwise/anticlockwise direction. The soiled stem

portion is cut with sharp

edged knife and mushrooms are collected grade-wise in baskets.

Dropping of the stem cuttings on the floor or the bed should be avoided, as these

will promote the growth of undesirable microorganisms. Cleaning of mushroom beds and floor

is recommended after each crop harvest. Fresh casing is applied at places from

where mushrooms have been removed. Water is sprayed at the rate the mushrooms have

been harvested, i.e. for every kg of mushroom harvested 1 litre of water is added after

harvesting. Damaged pins/mushrooms, if any, are also to be removed from the bed manually.

If bunching of mushrooms is observed, then there is a need to address the

climate controls for creation of optimal environmental conditions during pinhead formation.

Mushrooms after harvest are graded, packed in PP bags/card board

boxes and preferably chilled at 4°C for 6-8 hours before sending to the

market. The pre-market chilling enhances the shelf life of mushrooms. While harvesting

care should be taken to keep the pileus free from casing soil, as it stains the

mushrooms. Washing of mushrooms to make them extra white for increased acceptability in the

market is undesirable, especially with Potassium metabisulphite solution. Unwashed mushrooms stay

fresh for a longer period. Mushrooms should be handled carefully, and not bruised

during the harvesting operation. Bruising will damage the mushroom tissue, which will

turn the pileus dark/pink on exposure to air. While packaging mushrooms in PP bag one

should not forget to make a small hole (0.2 mm), as it will prevent the development

of aflatoxins in transit or storage.

Button mushroom can be stored at 4°C for a few days without any

deterioration in its quality but it is desirable to consume/market fresh mushrooms.

Since button mushroom has a very short shelf life and it cannot be stored for longer

periods, hence it requires processing for long storage. Mushrooms are best preserved in

brine solution after blanching, either in cans or jars. The properly processed

mushrooms stay in good condition for over a period of 1 year. It is possible to

transport canned mushrooms over longer distances without any deterioration in their quality. But

fresh mushrooms can only be transported short distances in refrigerated vans/by air to

reach up to a remunerative market.

B. Environmental Crop Management

Mushroom is an indoor crop, raised in cropping rooms with

simulated environmental conditions suiting to a particular mushroom. Hence management of

crop environment becomes utmost important. It includes the temperature, RH, CO2

concentration, air speed/evaporation rate over crop beds, air changes in the room/oxygen

availability and other such factors, which directly influence crop productivity.

The environment management in the cropping room includes

addressing of the

following factors:

1. Temperature

2. Relative humidity (RH)

3. CO2 concentration

1. Temperature

Temperature in the room has two areas for monitoring i.e., air

temperature and bed

temperature. Temperature has direct bearing on crop productivity in synergy

with other

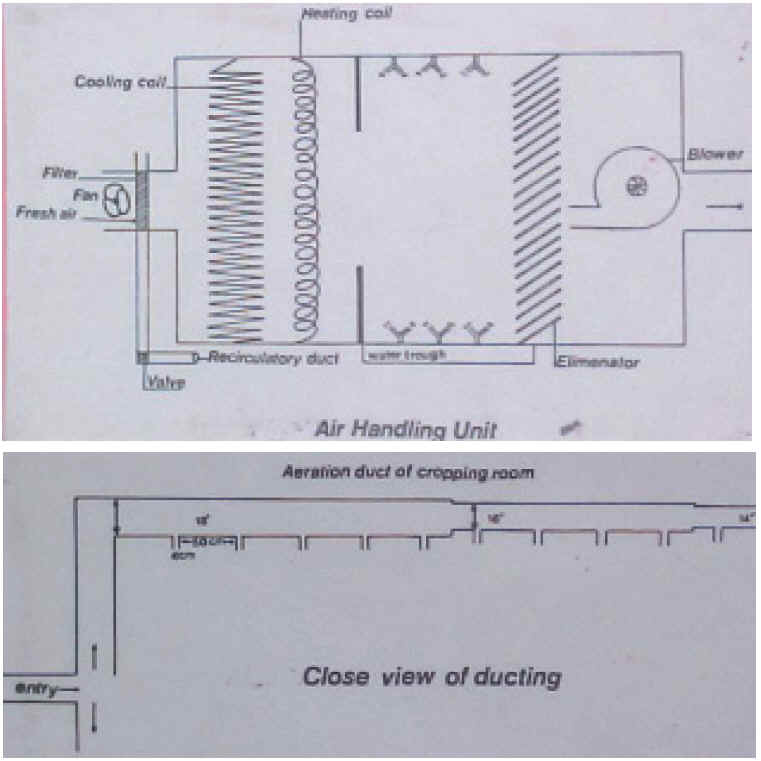

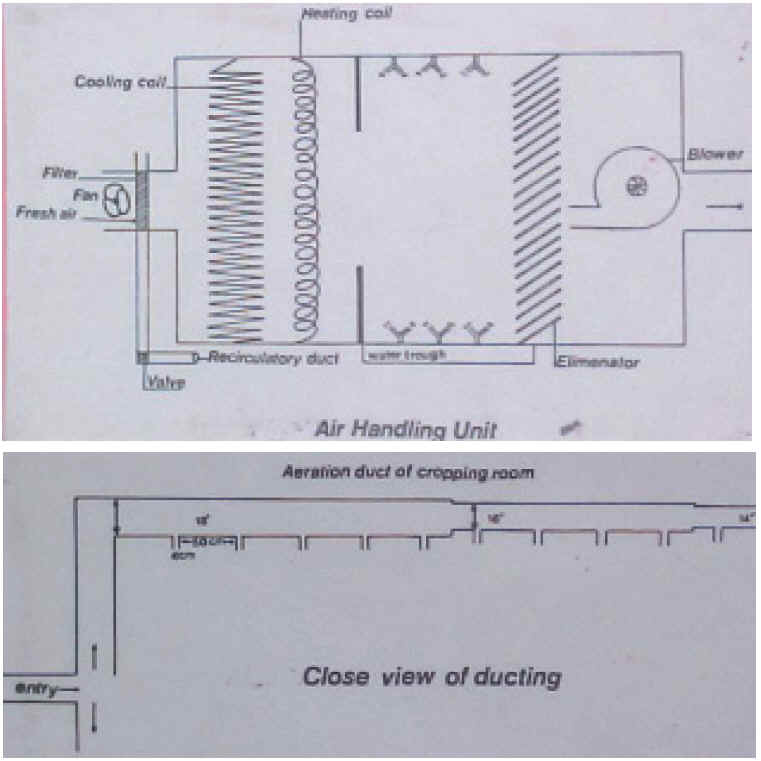

Fig. 4. Schematic

view of Air Handling Unit and aeration duct

f

actors like RH and CO2 /O2 conc. in the cropping room. The bed

temperature in the cropping room is directly influenced by the air temperature, so

it is the air temperature that has to be addressed. The air temperature inside the room

can be manipulated with use of cooling/heating coils in an Air Handling Unit (AHU)

installed inside or outside the cropping room for climate control. An independent AHU is

desirable for each cropping room. The AHU inside contains a set of cooling coils, heating

coils, RH fogging jets and a centrifugal blower fan for blowing the conditioned air into

the cropping room (Fig. 4).

The AHU is generally installed on top of the entry door and is

joined with a recirculating duct from inside the cropping room. The cooling coils are fed

with chilled water from the chiller, while the heating coils are fed with steam from boiler

and fogging jets get water from trough placed at the bottom of the AHU by a small pump. The

cooling requirement will depend upon compost quantity fed inside the room, outside

prevailing temperature, insulation on the walls, etc. The blower fan blows the

conditioned air into the room (Fig..3). The fresh air into the room goes in via AHU through a

control valve, and during most of the crop raising period fresh air valve is placed at 20-30%

and recirculating at 70-80% During spawn run the entire air is recirculated (100%) and no

fresh air entry is required.

a. Spawn run

For spawn run air temperature of 23 ± 1°C is maintained inside

the cropping room, which corresponds to bed temperature of 24-25°C (1-2°C higher

than air temperature). During this phase, the fresh air valve is closed and entire air

is recirculated, allowing the carbon dioxide to accumulate to the level of 15000 ppm,

desirable for quick spawn run.

Higher concentration of CO2 accelerates the spawn run/vegetative

growth of the mushroom. Any increase or decrease in temperature effects the

CO2 production of the compost and the RH of the room. With increase in temperature, RH

will tend to fall, and just vice versa with decrease in temperature. The properly

insulated room will ensure uniform temperature inside the cropping room at every stage of

crop growth. The heat from the cropping room is removed via cooling coils fitted

inside the AHU.

b. Case run

The environmental conditions suitable for spawn run, are

suitable for case run as well. The same conditions, as for spawn run will be continued

for next 7 days for case run, i.e., temperature of 23 ± 1°C in the air and 24-25°C in

the bed. The RH/CO2 will also be same as for spawn run. Under aforesaid conditions the case

run will be completed within one week, and at the same time the mycelium is observed

in the casing valleys. Valleys are the areas between the peaks as can be seen on top of

casing. The CO2 conc. and RH should also be maintained within the optimum range for quick

and effective case run.

c. Cropping

After completion of case run, cooling inside the room is

enhanced to bring the air temp. down to 15-17°C in the room within 2-3 days time.

Simultaneously, the fresh air vent is opened to 30% and rest of the air is recirculated (70%).

This brings down the CO2 conc. inside the room to 800 to 1000 ppm, desired for pinhead

formation. Likewise, the RH is also reduced to 85% from 95%. This facilitates pinhead

formation on the casing within a week’s time. The pinheads grow into full button sized

mushrooms in another 3-4 days. At this stage fresh air can be slightly reduced to

achieve 1000-1500 ppm CO2 concentration. The environment parameters are maintained as

above during entire period of cropping. Since the temperature has influence on RH and CO2

production from compost hence should be manipulated, keeping in mind its effect on other

two factors. All the three parameters work in synergy with each other to induce

pinning. The pinning will be affected adversely if any of these factors is not in its optimal

range. High temperature for a long period of time during cropping will

lead to sealing of casing, and will result in stopping of pinhead formation. The

mycelium will continue growing in vegetative phase and will seal the casing, making it

impervious to water, thus resulting in serious yield losses. The desired temperature in

cropping room can be maintained with good precision by the use of sensors and

controlling devices attached to cooling/heating coil inlets fitted inside the AHU. These devices

are easily available and are effective in temperature control in the cropping room.

2. Relative humidity

Relative Humidity (RH) is the ratio/proportion between absolute

humidity (AH) and saturation point of humidity (SPH) at a given temperature,

expressed in percentage. Absolute humidity is number of grams of water vapours contained

in a cubic meter of air at a given temperature. Saturation point of humidity is the

maximum number of grams of water vapours feasible in a cubic meter of air at a

given temperature. Relative humidity (RH) of 85% is necessary for obtaining

highest pin head formation in synergy with other factors like temperature and

CO2 concentration. RH of 85% permits slow evaporation of

water from the crop bed to air in the cropping room and thereby

facilitating the upward movement of nutrients in the compost. This exchange of

air facilitates loss of CO2 + heat into the air, necessary for healthy pin head

development and crop productivity.

In the event of RH falling below 85% inside the cropping room,

more moisture from the crop bed will be withdrawn resulting in drying of the

casing layer. This will seal the casing and result in crop losses. Lower RH in

the room will be indicated by bed temperature falling below the air temperature,

an undesirable situation to be avoided at any cost. Under normal circumstances

the bed temperature is always higher by 1-2°C than air temperature for

development of a healthy crop of mushrooms. For round the clock monitoring of

RH, monitoring of the bed and air temperature inside the room is desirable.

The incoming air should be humidified enough to prevent loss of

moisture from the crop beds. Evaporation of moisture from crop beds has to be

taken into consideration for calculating the g of water vapours required per m3

air in a room for maintaining the required RH for cropping. Air in a cropping

room contains 9.6 g water vapours per m3 of air at 14°C (A), the saturation

point of humidity at 14°C is 12 g/m3 (S). The RH of the room air will be A/S ×

100=9.6/12 × 100 = 80%. The ultimate expression is the quantity of water

vapours contained per m3 of the air space of the room at a given temperature. 31

g of water vapours gets evaporated from 1 m2 bed area at 17°C/85% RH/hour. The

change in room temperature will alter the RH in the room. Use of RH sensors with

cut off/starting devices for recording and maintenance of RH in a cropping room

is very useful. The sensors will control the fogging jets in the AHU as per the

requirement in the room. For obtaining a temperature of 17°C and RH of 85% in

the cropping room, air temperature is brought down to 14°C at exit point of AHU

with 100% RH. The air on reaching the crop bed will receive some heat from crop

bed and raise the air temperature to 17°C with RH automatically falling to 85%.

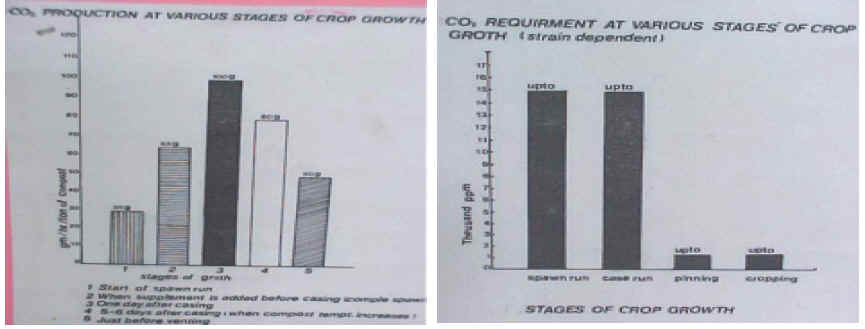

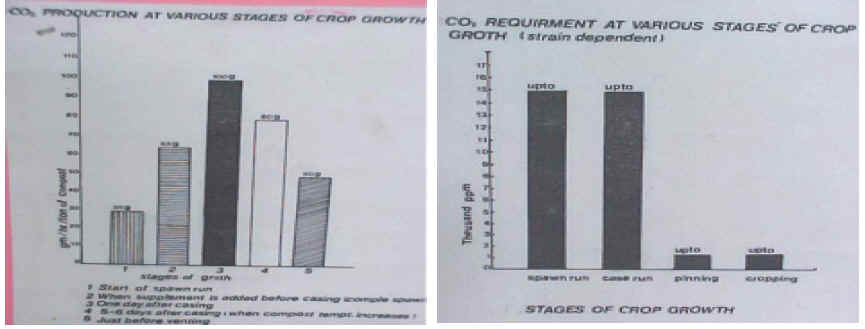

3. Carbon dioxide

Carbon dioxide concentration is the third important factor in

management of environment inside the cropping room. CO2 is produced by actively

growing microorganisms in compost during spawn run, case run and by mushroom

mycelia and mushrooms during entire cropping cycle (Fig. 9.5).

During spawn run, higher concentration of CO2 is desirable,

which helps in quick and quality spawn run. For spawn run, CO2 concentration

between 10000-15000 ppm is desirable (strain dependent) and it helps in quick

spawn run in compost. Higher concentration of CO2 is also desirable during case

run (Fig. 9.6). For pinning and cropping, the CO2 concentration is lowered

around ambient (800-1000 ppm). CO2 concentration upto 1500 ppm is maintained

during pinning & cropping, and this is done by venting/opening of fresh air

duct to bring in oxygen and exhaust of CO2 from exhaust vents under positive

pressure. The opening of vent will bring in fresh air, which is conditioned in

AHU (heated or cooled/humidified) and then blown into the cropping room via

ducts. The CO2 gets

Fig. 5. CO2

production during different

stages

Fig. 6. CO2

requirement at different stages

mixed up with the fresh air and is carried under positive

pressure towards the exhaust vent and finally exhausted. This also facilitates

the exhaust of heat alongwith the CO2 from the room air. The heat is removed via

cooling coils after the room air gets into the AHU via recirculating duct.

During air circulation, recommended air speed over the crop beds is 15cm/sec.

Ensure that the desired air movement is there in the central shelf in the middle

row. This can be checked with the help of a burning incense stick, which will

indicate the direction of air movement in the cropping room.

Higher concentration of CO2 during pinning can seal the casing

or produce onion shaped mushrooms with a bulbous base & a small cap. During

development from pinhead to button sized mushroom, higher concentration of CO2

will lead to long stiped mushrooms with a small cap (opened), which reduces the

crop yields. By gentle movement of air over the crop beds, the CO2 is carried

away from the crop canopy, thus saving the bad effect of CO2 trapped between the

mushrooms in the crop canopy. To ensure healthy crop production, about 6 air

changes per hour are recommended from the venting time to completion of first 2

flushes. During this period, CO2 production is highest (10 g/h/m2) and it

requires to be removed at a faster rate. Along with CO2, heat is also produced @

10W per hour from one m2 bed area at 17°C and 88% RH.

In subsequent flushes, 4 air changes per hour are sufficient to

maintain right O2 content in the cropping room (about 16%). During first two

flushes fresh air vent is opened to 30% entry and 70% recirculation, and in

subsequent flushes the fresh air vent is put at 20% and recirculation at 80%.

Use 2 μm mesh filters on fresh air entry points into the cropping room to

restrict the entry of diseases/competitor mould spores. The CO2 after mixing

with the room air, gets exhausted under positive pressure from exhaust vents,

thereby helping in heat + CO2 removal from the room. Maintenance of right

combination of casing moisture (about 50 ± 2%), CO2 concentration, RH and

temperature at

Fig. 7. High CO2

symptoms in button mushroom

pinning stage of crop growth helps in obtaining a heavy pin set,

thus resulting in a luxurious crop growth and excellent yield of mushrooms.

If onion sized mushrooms/drum sticks (Fig. 9.7) are observed,

correct air circulation for effective CO2 removal from crop beds is required.

Lack of air movement and accumulation of CO2 creates this type of situation.

Long stemmed mushrooms are again the outcome of CO2 accumulation in the air

around crop canopy due to faulty air movement/air circulation inside the

cropping room.

C. Airing Procedure for Fruiting

Venting or opening of fresh air for induction of fruiting after

case run is a critical phase in mushroom growing. Whether to cool first or bring

in fresh air first is a question bothering commercial mushroom growers. The

airing is done suiting a particular situation, whether one wants to have a heavy

first flush followed by moderate flushes later or equally spaced flushes. The

airing accordingly is handled under 3 heads:

1. Soft airing

2. Moderate airing

3. Severe airing

1. Soft airing

Soft airing means that we will have severe restriction on

venting to get smaller flushes suiting to market demand and the air is opened slowly.

The growing parameters to be manipulated for soft airing are listed below:

|

Air temperature

|

19°C in 48 hours

|

|

Compost temperature

|

21°C in 96 hours

|

|

CO2 concentration

|

4000 ppm in 48 hours

2000 ppm next 24 hours

1000 ppm after 72 hours

|

|

RH

|

98% to 92% in 48

hours

|

2. Moderate airing

Moderate airing means that we will have some restriction on

airing/venting to get well spaced flushes of moderate levels.

The growing parameters to be manipulated for moderate airing are

listed as under:

|

Air temperature

|

17°C in 24 hours

|

| Compost temperature

|

20°C in 72 hours

|

| CO2 concentration

|

2000-2500 ppm in 24 hours

Less than 1000 ppm in 48 hours

|

| RH

|

98% to 92% in 24 hours

|

3. Severe airing

Severe airing is done to obtain a heavy first flush and no

restriction is put on airing. This results in heavy pin set and large first flush, followed by

smaller subsequent flushes.

The growing parameters to be manipulated for severe airing are

listed below:

|

Air temperature

|

15°C as soon as possible

|

| Compost temperature

|

20°C in 48 hours

|

| CO2 concentration

|

Less than 1000 ppm in 12 hours

|

| RH

|

98% to 90% in 12 hours

|

|