White button mushroom

is a temperate mushroom requiring cooler climate for its growth. It is an indoor

crop and is an ideal tool in converting agricultural wastes in to proteinaceous

food. In early days its cultivation was mainly confined to the hills. In the

eighties growers realized the potential of this crop and started its cultivation

in the northern plains in the winter when the climate was suitable for its

growth. Many entrepreneurs in the plains further ventured and started its

cultivation round the year by employing artificial cooling facilities (chilling

stations). Today its cultivation is done through out the country Some are doing

it seasonally while many of them have preferred to go for round the year

cultivation. Today India boasts of having world�s biggest farm, the Agro Dutch

Foods Ltd, Lalru Punjab and many more environment controlled units exit in

different parts of the country cultivating this mushroom round the year.

Mushroom being an

indoor crop does not require arable land, except for some nonagricultural land

to build the infrastructure for preparation of substrate, raising of crop

preparation of spawn and postharvest handling. As mentioned above this mushroom

is grown seasonally and in environment controlled cropping houses and both

require building of basic infrastructure. Seasonal growing is done for 3-4

months when outside temperatures are favourable for the crop, i.e., during

winter months in N.W. plains and from September to April in the hills .

Seasonal cultivators of

this mushroom are using traditional methods of its cultivation and are mainly

cultivating this mushroom in the thatched structures employing long method of

composting. They usually take single crop in the entire season and are

harvesting 12-15 kg mushrooms/ 100 kg compost. Environment controlled units are

cultivating this mushroom round the year by having suitable infrastructure at

their disposal which includes a modern composting yard having bulk

pasteurization facilities. Of late few of them have shifted to indoor composting

while new upcoming units have chosen to produce their compost entirely by indoor

method. Besides these facilities they are having insulated cropping rooms and

other ancillary structures required for mushroom cultivation. Few of the bigger

units are having their own spawn lab and processing unit as well. An

entrepreneur can start mushroom cultivation modestly using seasonal growing

houses and after gaining sufficient experience can shift to round the year

cultivation employing suitable climate control facilities. Suitable

infrastructure including different machineries are required at the farm to carry

out different operations to govern the whole process of cultivation in such a

fashion so that one gets optimum returns from his farm in this competitive

environment. The one who designs the farm in most scientific manner looking to

the need of the crop and easy accessibility to the different infrastructure for

their operation convenience in less space, utilizing less money will gain

handsome returns in the years to come. Present chapter would deal in detail the

infrastructure and machineries required for the seasonal and environment

controlled units.

A. Selection of Site and Pre-Requisites

Before selection of site,

the following points have to be taken into consideration for greater operational

efficiency and cost effective production of mushrooms at the farm:

1. Chosen site should

preferably be away from the municipal limits and entrepreneur should purchase

sufficient land in one go looking to the future expansion.

2. The site should be

serviced by a motorable road, or nearer to a road head to reduce costs on

transportation of raw materials to the farm/finished product to the market.

3. Plentiful availability

of water at the site either through a perennial source or should have sufficient

underground water.

4. Easy availability of

raw materials especially straw and poultry manure around the chosen site at

cheaper rates in the area.

5. Availability of cheap

labour in abundance.

6. Uninterrupted proper

power supply at the chosen site.

7. Nearness to the market for the

proper disposal of the produce.

B. Components of a Mushroom

Farm

For round

the year cultivation of this mushroom employing environment-controlled

conditions a medium size plant would require under mentioned components.

1. Spawn

unit

For

producing in-house spawn for self requirement and for sale to other units. This

will have under mentioned major components.

a

Cooking/autoclaving room: For

boiling the grains and sterilization of the bottles/pp bags.

b

Inoculation room: For

inoculation of the sterilized bottles/ pp bags

c

Incubation room: For

incubating the inoculated bottles. Insulated and provided with AC.

d Cold

Store: For

storage of prepared spawn for its further disposal

Besides

above some ancillary structures like office, small lab space, delivery area,

etc. may also be required.

Machineries

required: Air conditioners, Laminar flow system, Autoclaves, BOD incubators,

Boiler, Boling cattles, Refrigerators, racks, pH meter, gas stoves, etc.

2.

Composting unit

This will have under

mentioned main components for production of compost

a Pre

wetting area: For

dumping of raw materials and their pre wetting (uncovered).

b

Composting yard: For

making piles out of the wetted materials (covered)

c Phase-I

bunker: For

phase -I composting (incase indoor composting is employed).

d Phase

-II tunnels: For

performing pasteurization and conditioning of the compost.

e Casing

soil chambers: For

pasteurization of the casing soil.

f Spawning

area: For

spawning of the prepared compost

Besides

above certain ancillary rooms like boiler room, underground service room, store

room, workers room, etc. would also be required Machineries viz., boiler,

blowers, air handling units, gratings, digital thermometers, compost retaining

boards, ventilation system for phase -I bunkers would be required by a medium

size farm (up to 200 TPA). Large farm besides above may require a front end

loader (Bobcat) and other compost handling equipments including turner, filling

line, etc.

3.

Cropping unit

A cropping

unit will have series of insulted rooms of designated size depending upon the

production targets. Besides rooms there will be AC/ compressor room, packing

room, central corridor housing air handling units and pipelines.

Machineries

required: Insulted doors, central chilling station (ammonia or freon based), air

handling units, computer based controllers (optional), racks, and trolleys,

harvesting trays, etc. would also be required. For continuous electric supply to

phase-I, phase- II tunnels and cropping rooms, generators of desired capacity

would also be needed.

4. Post

harvest handling unit

It will

have under mentioned components:

a

Pre-cooling chamber (cold room): For

storing the mushrooms before canning

b

Canning hall: For

housing the canning line for processing

c

Laboratory: For

quality control of processing

d

Store: For

housing the processed can

e

Office: For

sitting of the staff

f

Machinery required: Canning

line of desired capacity

5. General

Layout/Location of various Units

The layout

is so planned that all the infrastructures required to be built are accommodated

in least possible land without over looking mushroom cultivation requirements.

The general layout of a mushroom farm has to be carefully planned after

selection of the site, keeping in view the several factors including

accessibility of road to the composting yard as raw materials are to be dumped

here for their processing to the compost. Wind direction is also kept in mind

for choosing the location of the composting facilities. During most of the time

of the year wind should flow from cropping area to the compost yard and not vice

versa. Phase-I bunkers are constructed in line nearer to the phase -II tunnels

for their operational convenience and also to avoid heat losses. The bulk

chambers are built nearer to the phase-I bunkers. Both these structures are

preferably built away form the road at the distant end of the yard so that the

distant end of the phase -II tunnels opens nearer to cropping rooms and away

from composting yard (Fig. 8.1). The cropping rooms are built away from

composting area for reasons of cleanliness and avoiding contamination by pests

and pathogens. The casing pasteurization chamber is built nearer to the

composting yard or within the composting yard with small platform for preparing

the casing soil (Fig. 8.1). Enough space for future expansion of composting

yard, construction of more phase-I & II chambers and growing rooms should be

left vacant for planned development of a mushroom farm in a phased manner. Spawn

unit is built far away from the composting yard and nearer to the cropping area.

Processing unit can be a separate entity or can also be built within the

building housing cropping rooms.

The

foundation of the buildings is dug on the firm ground. The underground water

pipes, electrical cables and sewers are laid well before the actual construction

starts. The entire site area should preferably be fenced or brick walled for

security reasons. In areas where land is scarce, double story cropping houses

can be built to economize on space. The cropping rooms are generally built in

double rows with a path/gully in between for various operations and services.

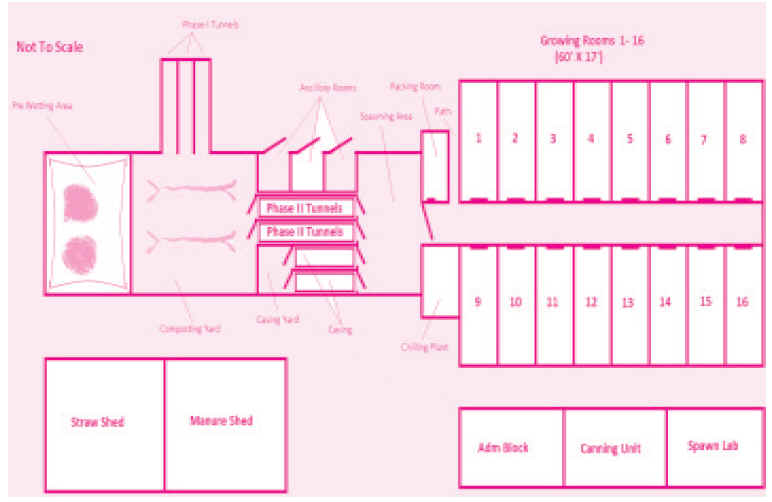

Fig 1. General

layout of the farm

a.

Composting unit

The

components of composting unit will depend upon the method of compost production

chosen. If one is going for indoor compost production, in such a case

requirement of composting yard will be greatly reduced and it will be 1/3 of the

normal yard required when one has chosen SMC. Now a days trend is for indoor

compost production due to environment legislation. In such a case a small pre

wetting area, and small covered composting yard would be required with minimum

of two-phase-I bunkers and one phase-II tunnel. Size of all these structures

would depend upon the production targets of the unit and size and numbers of the

tunnels.

b.

Prewetting area (PWA) (lagoon)

This area

is constructed nearer to the road. It is a simple cemented structure having a

saucer like depression in the center so that it looks like a lagoon and water

remain collected during the prewetting of the compost ingredients (Fig. 8.1).

Center of the lagoon should be around 1 ft deep. Excess water of the lagoon is

collected in a goody pit built specially for the purpose at a convenient place

around PWA for its reuse. Floor of the PWA should be such that it can withstand

the load of the front-end loader while performing the wetting operations. It is

usually not covered and is open to the sky. PWA terminates in the composting

yard. Water connection with 2"-3" dia. pipe should be available in PWA

permanently with additional portable hosepipe for use during pre-wetting. One

dewatering pump with a hose should be installed in the goody pit to pump out the

run-off water for its reuse during pre-wetting. Water in the goody pit may be

aerated continously to avoid foul smell.

c.

Composting yard

Fig.

2 Composting

yard including Phase-I bunker

The

composting yard (Fig.2) is required for phase-I of composting. It is a

prerequisite when one is going in for short method. The composting yard should

necessarily be a covered shed with 2-3 ft sidewalls on the two sides (length

wise) where rain will not interfere in the normal process of composting. The

foundation of the composting yard should be laid on a firm ground and it should

necessarily be reinforced if mechanization of the composting yard has to be done

as it has to withstand the load of heavy machines. The floor is given a run-off

of 1 cm per running meter away from the bulk chamber and towards the goody pit

end.

The roof of the

outdoor composting platform is built on tresses or RCC pillars 16 ft high with a

GI or any other suitable roofing. The covered The composting yard should be big

enough to hold maximum compost stacks for phase-I of composting. When adopting

indoor compost production wetted ingredients are just made up into a heap for

3-4 days and do not require rick formation in such a case a small platform can

suffice the purpose.

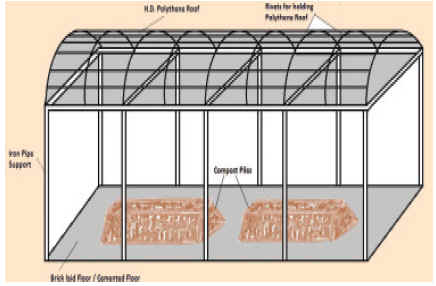

Fig 3. Low

cost composting yard

However, a

large composting yard would be required if SMC is adopted. On an average

one ton compost occupies about one meter length of the composting yard, with an

extra space of 2-3 m left on each side for turning with machines. Two bulk

chambers will have a platform with 10-15 m width. For two bulk chambers of 25

tons capacity each, a composting yard of 25 m x 13 m should be good enough to

concurrently run phase-I operation at a time for both the chambers. A drain

should run on the two sides of the platform to facilitate periodic cleaning. A

few three phase 15 amp. power connection should also be provided at the

composting yard for operating machines like hopper regulator, compost turner,

filling lines, etc. The yard should be well lighted with tube lights and strong

searchlights to facilitate round the clock operations at the composting yard

An

overhead water tank is necessary, particularly where water is scarce, to store

water for timely operations. The floor of the composting yard for long method of

composting should be simply cemented/brick layered with a low cost roofing of

high-density polythene fixed on iron tubular structure or it can also have

thatched roof (Fig. 3). In practice (90%) of the farms cultivating this mushroom

seasonally are preparing their compost in the open fields and do not have any

specially built composting yard built for the purpose. However, such growers are

facing lot of disease and pest problems. We recommend that the compost by long

method by seasonal growers should at least be prepared on a cemented platform-

let it be open to the sky.

d. Phase-I tunnels

(bunkers)

This

facility is required when indoor composting is employed at the farm. These are

specially built non-insulated tunnels having full width opening at the front

(Fig. 4). Dimension of the bunkers would depend upon the output of the compost

required. Generally the bunkers are 1.5 times more the size of the phase -II

tunnels. It has a plenum (ventilation duct) constructed below the actual floor.

A perforated concrete floor having around 1 cm openings at a distance of 1ft

each to the entire floor area is constructed above the plenum or it has simple

RCC /steel gratings having 20% opening to the entire surface area of the tunnel

(Fig. 5) which is serviced by a centrifugal fan having 1/4th the capacity of

phase two blower which means that a ventilator having air displacement of 50 m3

per hour ton of compost at 50 mm WG water pressure would suffice the purpose. A

plenum floor involves pressurizing the entire airspace beneath the concrete

floor, allowing the air to move up into the substrate through the holes or

through series of slates.

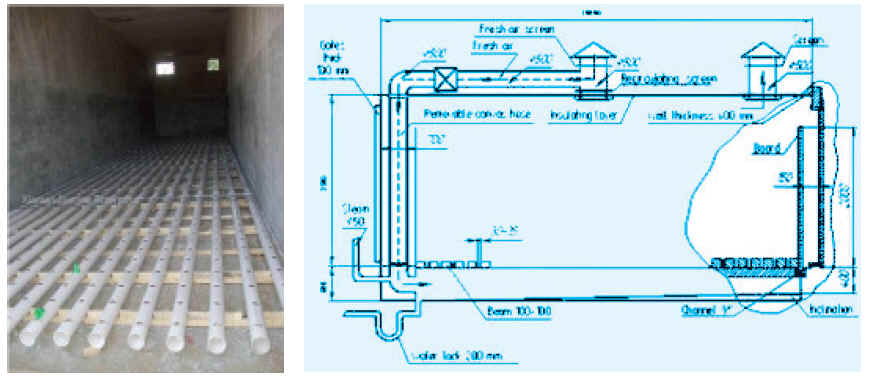

Fig. 4. Bunker

Fig. 5. Gratings

over the plenum

Alternatively

the bunkers have no plenum and several pipes (5-15 cm dia) are buried in the

floor along the full length of the bunkers having small holes (5-10 mm dia) at a

distance of 15 to 30 cm each (Fig. 6). These pipes converge into a manifold,

which in turn is connected to a high-speed blower fan (around 1000 Pascal). A

timer is usually attached to the blower, which pulsates the air in the bunker

periodically as per the setting of the timer. A minimum of 2 such phase-I

tunnels (bunkers) are required.

Fig. 6. Bunker with

aerated pipes

A bunker for 20-25 ton compost output at the time of

spawning may have thedimensions 45 x 10 x 8 with 9 pipes of 2.5 m dia. at

distance of 1 ft. (6� from the wall). To equalise the pressure either the pore

size may be increased or distance between the holes may be gradually decreased

from 1.5 ft. to 9�. These 9 pipes are linked to a bigger pipe of about 6�

dia. which inturn is linked to a centrifugal blower.

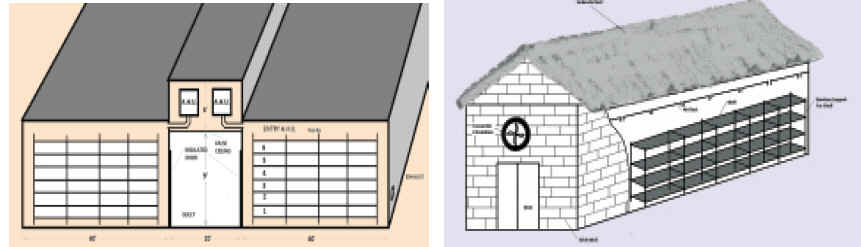

i. Pasteurization facility

A modern farm employing either indoor method or SMC essentially

requires this facility. The bulk pasteurization chamber is principally used for

phase-II of composting for pasteurization and conditioning of the compost. For

this purpose, an insulated chamber is built with facility for steam injection

and controlled recirculation and fresh air entry in the tunnel through a blower.

The insulated chamber is built with purpose of cutting off the external

environment and simulating a desired environment inside for controlled

fermentation of the compost ingredients.

In Bulk pasteurization chamber compost is handled in bulk inside

the tunnel or chamber and hence the name bulk chamber. The compost after phase-I

is filled into specially built chamber, which is properly insulated and provided

with steam connection and air blowing system for re-circulation. The compost is

filled in the chamber on top of its grated floor built over the plenum. The

plenum has an air circulation duct used during pasteurization/conditioning (Fig.

7).

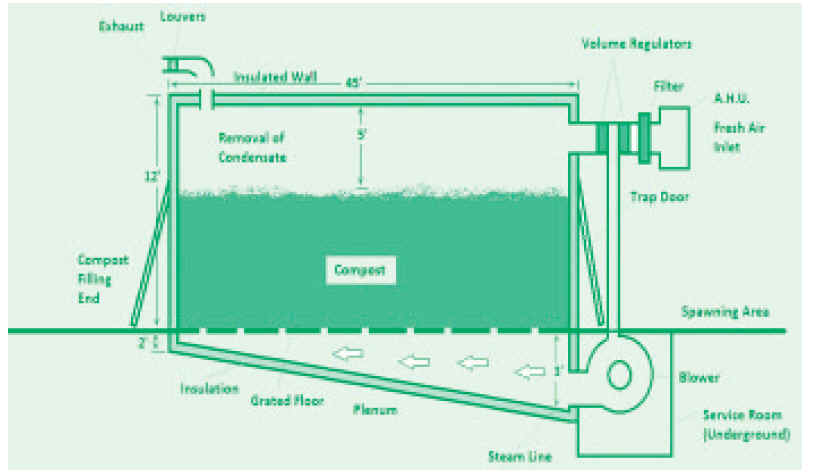

Fig. 7. Cross-section of the bulk chamber

(45� x 9� x 13�)

The bulk chamber should be constructed on one end, (away from

road) of the composting platform. One end of the bulk chamber should open into

the platform and the distant end in the clean spawning area. The foundation of

the bulk chamber should be dug on a firm base ground. The floor must be laid

with a good run-off provided with a drain to facilitate cleaning. It is

pertinent here to note that this floor is given a slope towards the service area

end (blower end). A large tunnel will be around 90 cm deep towards the blower

end while it will be around 15 cm deep towards other end (filling end).

Floor should be properly insulated with thermocol/glass-wool 5

cm thick (15 kg/m2 density). The insulation is covered with isolating membrane

of PVC sheeting followed by 5 cm cement floor and finally the finish. Such floor

is constructed for both cropping room and the chamber. The walls should be

9" thick (one brick lengthwise) built over the concrete foundation. The

length and breadth of the bulk chamber will vary, depending upon the amount of

compost to be treated in the chamber, with the height of 13 ft, the roof is made

of 4" thick RCC. The walls, ceiling and the floor below the plenum are

insulated with 5 cm thick insulating material (15 kg/m2 density) necessary for

effective insulating effect during pasteurization and conditioning of the

compost. Required K value of the insulating material should be around 0.5-0.6

kcal/ m2/h. Air leakage in bulk chamber must be prevented at any cost. The bulk

chamber has two floors one is real insulated floor while another false or grated

floor, which is laid above the actual floor or plenum over the ventilation duct.

The grated floor must allow the air to pass through, for which approximately

25-30% of the floor area is left in the form of gaps for ventilation/circulation

of air and steam. The plenum is divided with a perforated brick wall (one or

two) in the centre for supporting the grated floor. The gratings can be made of

wood (painted with bituminous paint), coated iron strips mounted on angle iron

frame or with concrete beams. Alternatively a concrete floor can be poured over

the plenum as in case of phase -I tunnels having openings. If nylon nets are to

be used for mechanical filling and emptying, then cemented grated floor with

appropriate RCC strength is built specially for the purpose. The doors of the

bulk chamber are made of angle iron or wooden frame with 2-3" insulation in

the middle and covered on both side with aluminum sheets, else they can also be

made up of puff panels. The chamber will have two exhaust vents, one for

recirculation exit and the other for exhaust of gases on introduction of fresh

air via dampers.

The steam line is also connected at the entry point of the

blower. The walls and ceiling can be damp proofed by coating bituminous paint on

inside over the cemented surface, which will also serve as an effective vapour

barrier. The grated floor inside and the work floor outside should be of the

same height for operational convenience especially when tunnel has to be filled

mechanically.

Two types of tunnels (bulk chambers) are in use, two door bulk

chambers and single door bulk chambers. In the single door bulk chamber, the

same door is used for filling and emptying and the other end is utilized for

fixing installations (blower, etc.). In double door bulk chamber, one door is

used for filling (which opens into the composting yard) and the other for

emptying (opening into the sterile spawning area).

The bulk chamber can be filled/emptied manually or by conveyer

belts. The uses of machines for filling/emptying are labour saving, time saving

and ensure homogenous filling as well as maintenance of absolute cleanliness

during operations. For mechanical emptying two nylon nets are used, one fixed

over the RCC grated floor (gliding net) and the other moving over the

lower net (pulling net). The compost when brought out is fed into the

spawn-dosing machine where requisite amount of spawn is mixed with the compost

and the seeded compost is then poured into clean polythene bags for transport to

the growing rooms.

The dimension of the tunnel for producing 20-25 ton of compost

are 36� x 9� x 13�. One may replace the plenum with plastic pipes fitted

with spigots (Fig..8). The centrifugal fan can be placed at the bottom as well

as on the roof (Fig. 9) depending upon the space and design.

Fig. 8. Plastic

pipes ready for spigot

fitting

Fig. 9. Line

drawing of Phase-II tunnel for 20-22 ton compost output

(Source:

http://www.21food.com/)

(Source: http://www.agaricus.ru

)

e. Air handling units of the tunnel (AHU)

For effective pasteurization and conditioning of the compost in

the tunnel specific requirements of air and ventilation are to be met, which are

generally met by providing/installing AHU in the tunnels (Fig. 10). Effective

pasteurization and conditioning is attained when 150-200 m3 air per ton of compost per hour is

blown through the compost mass. For this purpose high speed centrifugal fan is chosen and

is placed on the slope end of the ventilation duct in the underground service area.

Compost is spread over the plenum on the grated floor in about 2-2.2 meter thick layers.

Nylon nets are generally placed under the compost if mechanization is necessary. These

together give a resistance of around 60-65 mm WG during pasteurization taking together the

resistance of the air ducts, the in and out openings, the perforated floor, etc. the

static pressure of the blower fan should be around 100 mm WG at 150-200 m3 air per ton of

compost per hour. Blower fan must be well protected internally and should be made up of

sheet steel. Aluminum is ideal for air ducts and should at least be 2 mm thick and there

should not be any leakage in the duct system. Ducts are generally insulated with glass

wool or any other suitable material. Fresh air is regularly required in the tunnels and

since this air is drawn from the open atmosphere, chances of fungal spore�s contamination are

likely and hence the incoming air in the ventilation duct should be filtered and

should pass through 2 mm fungal spore filters. The pre filters and filters should be

washed at regular intervals. The inlet and exhaust openings must be fitted with a flap valve,

which opens only when positive pressure is created inside the tunnel. The

dimensions of inlet and exhaust openings should be the same.

Since, India is a tropical country where temperature during

summer months goes above 45�C. Cooling of compost for spawning during this period

becomes difficult by simple introduction of fresh air. Special cooling arrangements

are therefore required to be made in the AHU of the tunnel for this purpose. A ten ton

capacity cooling equipment or cooling coils from the central chilling plant is installed at

the top of the AHU or such coils can be fitted in the blower section of the AHU. This arrangement

is very effective in cooling of the compost in tropical areas during summer months.

Installation of such facilities however requires heavy investment. Compost during these months

can satisfactorily be cooled during nights when the temperature is low.

f. Casing pasteurization chamber

Casing pasteurization chamber is just a mini bulk chamber. It

has all the necessary components as required for the tunnel. Only difference is that

the plenum is not having any slope and capacity of the blower for proper steam injection

and its uniform distribution inside the casing mass is around 1/4 the capacity of the tunnel

(Fig. 11). The size of the chamber will depend upon the size of the compost chamber and the

size of the growing rooms. One chamber load should provide casing for one compost

lot from each tunnel.

The casing inside the chamber can be treated in the bulk and in

such case it is filled up to the height of 90 cm only as against the tunnel where compost is

filled upto the height of 2-2.2 meters. Else casing after wetting is filled into the

perforated wooden/aluminum trays which are stacked one over the other inside the chamber and

steam treated at 65�C for 6-8 hours. This chamber can be built near to the composting yard

or within the composting yard with a separate casing mixing platform.

Fig. 10. Tunnel

with air handling

unit

Fig. 11. Casing

pasteurization chamber

g. Spawn unit

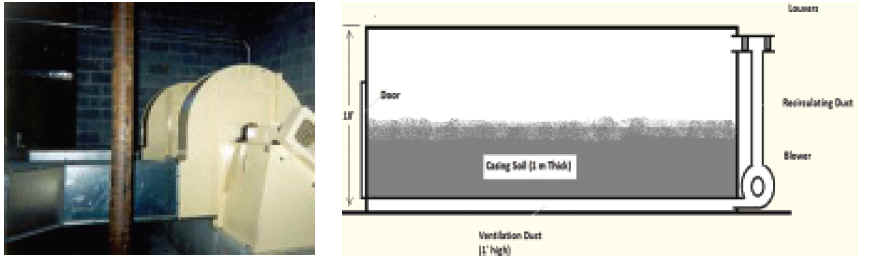

The layout plan of a spawn laboratory is given in Fig. 12. A

total built in area of 60� x 30� x 12� should be good enough to house the entire spawn

unit. This area will be divided into different work areas like boiling/autoclaving room,

inoculation room, incubation room (insulated and with AC), cold room (heavily insulated with

chilling facilities), store, office and delivery area.

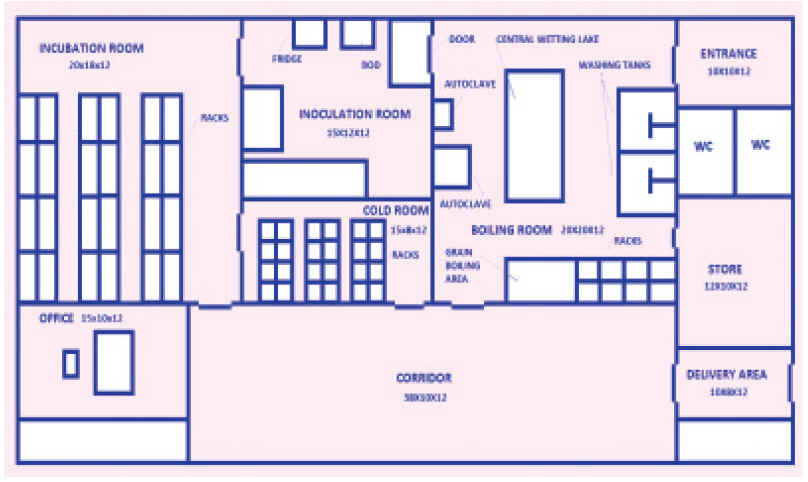

h. Cropping unit

Since mushrooms are grown indoors under simulated environment

specially created for mushroom growth, the cropping rooms are required to be built

specially for the purpose Two types of cropping rooms are built suiting to particular

requirement - those required for seasonal growing and those for environment controlled growing round the year

(Fig. 13).

Fig. 12. Layout

of plant of a spawn lab

Seasonal cropping rooms:

Seasonal

cropping rooms are simple rooms with modifications for maintaining various growth parameters. These

cropping rooms will have a cemented floor, cemented walls, cemented ceiling or a

false ceiling with arrangement for forced air circulation inside. The seasonal

cropping rooms are built of simple brick walls with roof made of asbestos sheets and a false

ceiling. The room is more or less made air tight to make the air handling system work

effectively for obtaining necessary air changes during growing. No insulation is required

for seasonal growing rooms, as it will not allow heat dissipation from the room

efficiently. These simple rooms are used for seasonal mushroom growing, coinciding various

phases of growth with prevailing outside temperatures. No energy is generally used for

heating/cooling of the rooms under seasonal growing conditions. However few units in

plains have installed heavy-duty coolers to bring down the temperature in summer

conditions. The cropping rooms for seasonal growing can also be made with a thatched roof

and a false polythene ceiling. The door is installed on one end and the exhaust vents

on the opposite end of the door (Fig. 14). The mushrooms are grown on beds made out of

bamboo sticks and sarkanda stems (a plant abundantly growing as a weed in North

western plains of India). These growing rooms can also be built as low cost structure,

steel pipe frame with highdensity polythene covering from outside. The real low cost growing

houses built in rural areas are made of walls, roof and door of sarkanda.

Fig .13. Cropping

section of the mushroom

unit

Fig. 14. Cropping

section of the mushroom unit

The mushroom houses made with bamboo frame and synthetic fiber

cloth material, both inside and outside, with paddy straw insulation in between

has also given good results under hill conditions for seasonal growing.

i

. Environment controlled cropping rooms

The environment controlled cropping rooms are built like

hermetically sealed chambers where the air movement is controlled either manually or

semi automatically with mechanical control systems. These cropping rooms are

appropriately insulated and the dimensions of a cropping room are determined by the

amount of compost to be filled into the room. Rooms with greater length and narrower

width gives better results as far as air handling inside the room is concerned. A cropping

room, with a capacity to take compost from one bulk chamber, is considered advantageous as one

bulk chamber load can straightaway be filled into one cropping room. Further,

cropping cycles to be taken will determine the numbers of growing rooms in the unit.

Now a days 60 days cropping cycle is generally taken and in this manner a minimum

of six crops are taken / room in a year. In such conditions a minimum of 12 rooms are

required to have constant supply of mushrooms from the unit round the year. In this case

every room is filled with the spawned compost every after 5 days. Both bulk chamber and

cropping rooms of 20-25 tons compost capacity are considered to be operationally

efficient, as the filling/emptying operation and spawning can conveniently be done in one

day when machines are not to be used. However, bigger units may have the growing

rooms handling compost to the tune of 60 tons or more. Growing rooms are such designed

that maximum compost can be accommodated in least possible area without over

looking to the mushroom growing requirements. To give an example a room size of

60 x 17x 13 ft can easily accommodate 20-25 tons of compost when cultivation is

done in shelves or bags. The foundation of growing rooms should be laid on dry and firm

ground. The floor is laid as explained for bulk chamber. The walls will be made of

one brick thickness (9"thickness) and ceiling made of 4" thick RCC. The growing

rooms will have a single insulated door and 2 vents for exhaust on the back wall 2-3 ft

above ground level. One opening is provided on top of the door for entry of the Air

Handling Unit (AHU) delivery duct or for fresh air intake inside the room through AHU. The walls,

ceiling and floor should be insulated with 5 cm thick insulating material. The room should

be made airtight and all leaks closed to prevent ingress of heat from outside. The

cooling, heating and forced air circulation in the growing room is done via AHU installed for

each cropping room individually. The floor and walls of the cropping rooms should

have a smooth finish.

j. Structural details special to cropping rooms

i. Floor

The floor must be well laid out and should be strong enough to

take the heavy load of metal racks to be kept inside for growing mushrooms. The

floor should be insulated with insulating material 5 cm thick (sheets of thermocol or

glass wool or polyurethane). The insulation should be protected by a PVC sheeting, below and

above, against moisture. It is then covered with wire mesh and finally 5 cm thick

concrete floor is laid on top, which is given a smooth finish. The floor should have slight slope

towards the entry point for discharge of cleaning water and placement of formalin trough for

foot wash. The trough is connected near the wall to an exhaust drain to carry washings

from the room. The water discharge hole is protected at this point to prevent

leakage of air from the growing room. PUF pads can also be used specially in place of wall between rooms.

ii. Walls

The walls are made

of brick 22.5 cm thick, which are given a smooth finish with cemented plaster. The insulation sheets are fixed on the walls

(5 cm thick thermocol, glass wool/polyurethane), with the use of hot coal tar. Holes

are drilled on four corners of the sheet/inside the cement wall for expansion fasteners which

are fixed by screwing in the nail with 4"-5" long steel wire tied on its head.

The wire hangs out of the sheet to be used for tightening of wire net fixed on top of the insulation.

The layer of cement plaster is then applied (2 cm) on top of this and given a smooth finish.

Bituminous paint is applied on cement plaster as a vapour barrier. The painting can

be avoided in cropping rooms if the cook out is not done by steam. This wall will be

good enough to give a Kvalue of 0.5-0.6 kcal/m2h, even lesser and will facilitate proper

control of climate inside the cropping room.

iii. Roofs

The roof is made of RCC (1 : 2 : 4) 12-15 cm thick. The inside

is given a cement plaster finish for application of insulation (as explained for

the wall). The roof on the outside is protected by tarring it on top, followed by 10 cm

thick loose soil, 5 cm thick mud capping and finally the tiles. This will protect the roof from

weathering effects of rain and will ensure longer life of insulation and prevent seepage of

moisture into the room in rainy season. In hilly areas with a high rainfall index,

slanting GI sheet roof over the insulated RCC roof will be excellent and in that case mud

capping/tiling of the roof is not required.

iv. Doors/vents

The doors of the bulk chamber and the cropping room are made of

wood or angle iron frame covered on inside and outside with aluminum sheets/GI

sheets with insulation of 5-7 cm in the middle. The doors will have a rubber gasket

lined on inner periphery so that the door becomes air tight when closed. The door will

operate on hinges, with a strong locking latch for opening and closing of the door. The

exhaust vents are fitted with wire net, louvers and insulated lids. The louvers allow the CO2

laden air to exhaust under positive pressure created by the blower inside the air handling

unit.

v. Lighting arrangement

There should be a provision for tube lights and a mobile strong

light for inspection in each cropping room. The tube lights should be protected with

water proof housing. The tube lights should be fitted on all the walls vertically at

various heights to facilitate lighting of all beds. There should be provision for a few electric points

(5 and 15 Amp.) for operation of water spraying equipment and CO2 measuring

instruments.

vi. Water connection and sewers

One clean water pipe line (1" or 1.25") with tullu

pump installed to it for delivering clean water for spraying should be provided in each room.

Underground drainage line for carrying the washings from the room and wash basin discharge

should be laid before construction of the building. This waste water line should be

connected to the common sewer. In H.D. polythene cropping rooms, sunkun traps on the

floor for fresh water and drainage water are provided inside the growing house with each

trap of 1� x 1� x 1� dimension fitted with an iron lid on top. It is desirable to lay underground

drainage in the central gallery in advance of erecting the structure for

carrying away the waste water/washings from the cropping rooms.

vii. Gallery

The gallery between the rows of cropping rooms should be wide,

(12-15 ft) to allow efficient performance of various operations. The height of the

gallery should be same as for the growing rooms alternatively it may be about 8' with a

false ceiling, leaving another 5 ft above for pipeline and space for AHUs.

viii. Racks

Racks are made up of the angle iron for horizontal and vertical

support with iron mesh strips used for the shelves for housing compost. Length

(vertical axis) of the racks is generally made up of 5 cm thick angle while horizontal

support is made up of 3.5-4 cm thick. Width of the each shelf on the racks should not be more

than 135 cm in any case as width more than that creates hindrance in performing various

operations during cropping and most important of that is harvesting. Cultivation can be

done in bags or in shelved beds. Five to seven rows of shelves (depending on height of the

room) can be provided one above the other in the racks keeping a minimum distance of

60 cm in between. This distance can slightly be narrowed down if cultivation is

employed in shelved beds. In such a case all the four sides of the shelf should be provided

with 15- 20 cm high iron sheets for housing the compost in the beds. If more than 5

shelves on each rack are kept in the room than there should be provision of trolley running in

between two rows of racks just above the fourth shelf for carrying out the various

operations. Depth of the compost in shelves is generally kept at 15-20 cm while bags can be filled

up to the maximum height of 30 cm. A room of standard size (60 x 17 x 12 ft) can

accommodate 2 rows of racks each 4.5 ft. (135 cm wide). This will absorb 9 ft (270 cm) of the

room and the rest 8ft can be used to have one central path of 3 ft. and 2 side paths of 2.5

ft. Length of each rack would be 52-55 ft.

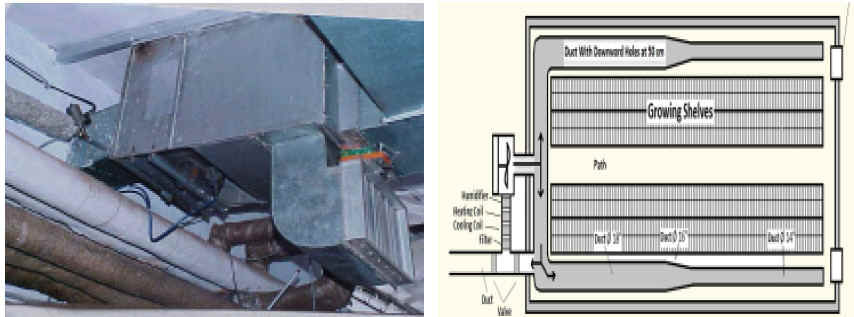

ix. Air Handling Unit

This unit is employed for creating proper weather inside the

growing room specific to white button mushroom. Air handling unit is generally

installed in each room at the top of the door, which is made up of aluminium or

G.I. Sheets. In certain cases it can also be placed on the top of the floor of

the growing room or in the corridor. Indirect cooling of air through chilled

water (5-60C) is generally employed in mushroom cultivation. Mushroom generally

require 225 m3 of air per hour per ton of compost. To meet this requirement a

high speed centrifugal fan of required capacity having working pressure around

50 mm WG is generally mounted in the body of AHU (Fig. 15). Alternatively if the

capacity of the growing room is to accommodate around 20-25 tons of compost,

then a fresh air fan of 600 mm dia of low pressure can also be chosen for this

purpose, but in such case a booster fan of 375 mm dia will also required to be

mounted in AHU for extracting fresh air from outside (Fig. 16). In AHU cooling

coils, humidifiers, heaters, eliminators and other components of AHU are mounted

on the back of the supply air fan. Cooling coils are generally connected to the

chilling unit via insulated ducts, which supply chilled water at 5-60C to these

coils. This water is generally chilled in an insulated tank or by cooling unit

comprising of a compressor, condenser, evaporator and a cooling tower. Heating

unit of AHU can employ strip heaters or steam through a low-pressure boiler.

Humidifiers can use free steam

Fig .15. Mdoified

AHU with fresh air fans

Fig.

16. A standard AHU with

centrifugal blower and ducts inside the growing room

from the boiler

to generate required humidity in combination with air pressure or can employ fine jets, which produce fine mist of

water in the humidifier section of the AHU. PVC eliminators, eliminate the free water

going inside the growing room. Booster fan in combination with supply air fan supplies

fresh air inside the AHU through fresh air dampers. Since fresh air coming from outside

atmosphere may contain fungal spores, which may contaminate the crop, this air is

generally passed through pre filters and a HDPE micro filter section (2-5 um). The AHU has a

mixing chamber with recycling dampers, which can regulate supply of fresh air or

room air inside the growing room. Out let of the AHU is connected to the distribution duct

in the growing room, which is generally made up of PVC sheeting having its end month

closed. It hangs below the ceiling in the central corridor of the room. This duct has ports

(5 cm dia) facing downward at a distance of around 50 cm each. When the air is blown inside

the room via AHU a positive pressure is created and CO2 laden air of the growing

room is expelled in the atmosphere through an outlet. In such cases back vents are not

provided in the growing rooms. Alternatively AHU can be so fabricated having provision

to exhaust CO2 laden air of the growing room in the atmosphere through an out let. In

such cases back vents are not provided in the growing rooms Central cooling unit can employ ammonia, freon or vapour

absorption machine (VAM) for cooling purpose. If size and capacity of growing unit

is small, say 250 MT per annum employing around 12 rooms then cooling employing

evaporator, inside the AHU can also be chosen. In such a case each AHU will be a self

contended cooling unit,

Fig..17. An

automatic canning line

employing, compressor, condenser and an evaporator. This unit will also have heating

and humidifying arrangements.

k. Processing unit

Design of the processing unit with its various components is given in the Fig..17

& 18. Utmost strict hygienic conditions are required to be maintained in the canning

hall and hence special care has to be given at this front while designing/ constructing

canning unit. The floor must be well laid off preferably having kota stone having slope

at one end. Walls should have ceramic tiles up to the height of

5-6 ft. Height of the canning hall should be not less than 14 ft in any case.

Surrounding where this facility is built should be clean and away from the composting yard.

Floor of the canning hall should have enough strength to support

the weight of different utilities to be installed required for the canning

operation. Canning hall should be big enough looking to the future requirements or processing

of other items. All the doors and windows should have wire mesh shutters to prevent the

entry of insects and flies. Three-four exhaust fans should be installed in the hall

at the appropriate places.

Cold room should be properly insulated with minimum of 10 cms

insulating material and separate product cooler of required tonnage should be installed

to it. FPO license is required for processing purpose.

Fig. 18. Design of

a canning unit