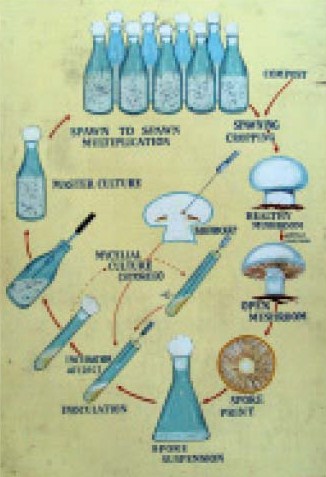

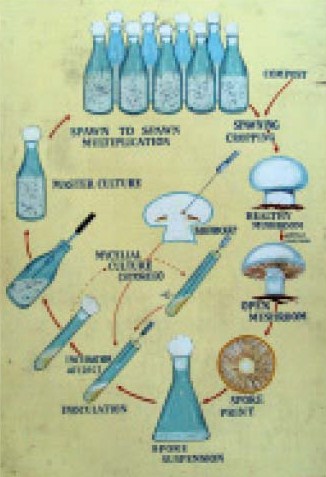

Fig. 5.1. Spawn production technology

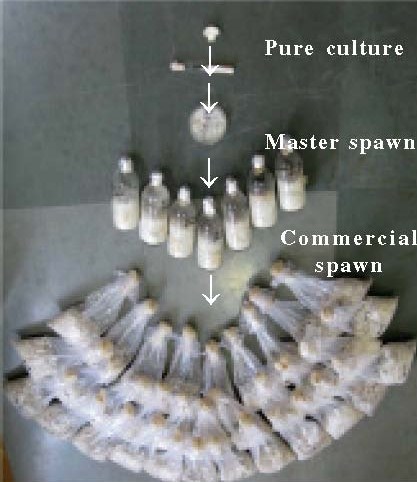

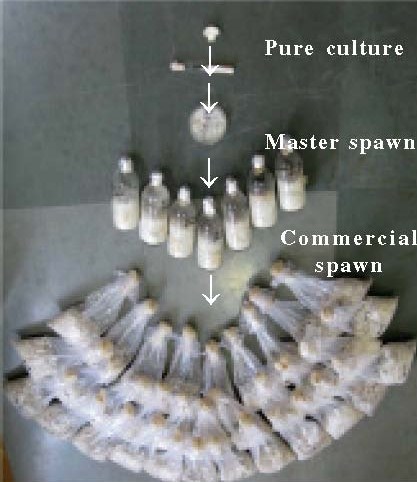

Fig. 5.2. Steps in spawn production

| Spawn Production Technology |

Technology

for hybrid seed production |

Spawn, i.e. seed required for growing mushroom, is the vegetative mycelium from a selected mushroom cultured on a convenient medium like wheat, pearl millet, sorghum grains, etc. In simple words spawn is grains covered with mushroom mycelium. It essentially involves preparation of pure culture of mushroom from tissue/spores, evaluation of selected cultures for yield, quality and other desirable traits, maintenance of selected cultures on suitable agar medium, followed by culturing on sterilized grains and further multiplication on grains. From 1652 to 1894 A.D. spawn was gathered from the wild rather than made and was referred as Natural or Virgin spawn (from pastures & meadows) and Flake spawn (breaking of beds through which mushroom mycelium has run), Mill-track spawn (bricks dried and made from mixture of horse dung, cow dung and loam soil). In the begining of 20th century pure mycelial culture were made and used for making manure spawn on sterilized horse manure or compost manure.

The process of making grain spawn was first introduced by the Pennsylvania State University in 1932. Grain spawn had an advantage over manure spawn as it could be mixed easily and provided many inoculum points. The grain spawn was further perfected by Stoller in 1962. Today most of the traditional spawn laboratories world over are using wheat, rye and millet grains as substrate for spawn production and are following the standard technique of mother spawn from pure culture mycelium grown on synthetic medium. The spawn production technology is divided into following steps (Fig. 5.1 and 5. 2).

Fig. 5.1. Spawn production technology |

Fig. 5.2. Steps in spawn production |

Pure culture of mushrooms can be prepared either by multi-spore or by tissue culture. Multi-spore culture is made from spore print that can be obtained by hanging a alcohol sterilized fresh fruit body on a loop of wire above a petriplate/sterilized paper. Spores are serially diluted and transferred to sterile potato-dextrose-agar (PDA) or malt-extract-agar (MEA) culture slants. These slants are then incubated at 25°C ± 2°C for 2 weeks to obtain pure culture. For tissue culture, mushroom after alcohol sterilization is cut longitudinally into 2 halves and bits from collar region (i.e. junction of cap and stalk) are transferred to pre-sterilized PDA or MEA culture medium, which is, incubated at 25°C ± 2°C in BOD incubator for one week. Mycelium from growing edges is carefully transferred to MEA/PDA slants and again incubated for 2-3 weeks to obtain pure cultures. Basic materials and equipment required for obtaining pure culture is given in Fig. 5.3.

|

| Agar Agar | Malt Extract | Auto clave | Slant |

|

| Tissue selection | Inoculation | BOD incubator | Pure culture |

Fig. 5.3. Preparation of pure culture

B. Substrate PreparationMushroom spawn can be prepared on any kind of cereal grains like wheat, jowar, bajra or rye and on agricultural wastes like corn cobs, wooden sticks, rice straw, saw dust and used tea leaves, etc. Spawn substrate i.e. cereal grains should be free from diseases and should not be broken, old and damaged by insect pests. Most of the cereal grains are good substrate for spawn production of white button mushroom (Agaricus bisporus and A.bitorquis), oyster mushroom (Pleurotus spp.) and paddy straw mushroom (Volvariella volvacea), but wood rotting fungi like shiitake (Lentinula edodes) and black ear mushroom (Auricularia spp.) grow better on saw dust based substrates over cereal grains. The grains are thoroughly washed in sufficient water three to four times to remove soil debris, straw particles and undesirable seed of grasses, weeds, etc. Washed grains are then soaked in sufficient water for 20-30 minutes and boiled in a container for 15-20 minutes. It should be ensured that grains get boiled but do not burst and same can be tested by pressing the grains. Normally for soaking and boiling 20 kg of wheat grain, 35 liters of water is required. Excess water from the boiled grains is removed by spreading boiled grains on sieve made of fine wire mesh or muslin cloth. The grains are left as such for few hours on the seive so that the water on surface gets evaporates. Now the grains are mixed with gypsum (Calcium sulphate) and chalk powder (Calcium carbonate) so that the pH of the grains is around 7 to 7.8 and they do not form clumps. Different people have given different ratios of Gypsum and Calcium carbonate. The best results are however, obtained by using 200 g gypsum and 50 g chalk powder for 10 kg grains (dry weight basis). First

(a) Boiling, seiving, autoclaving and inoculation |

(b) Method of inserting ring, folding bag and plugging |

(c) Preparation of master spawn and commercial spawn |

Fig. 5.4 (a-c). Steps of substrate preparation

gypsum and chalk powder are separately mixed and then they are thoroughly mixed with the grains. This mixing should be done on a smooth surface after wearing gloves. For commercial spawn production rotating drums can be used for uniform mixing. Different steps of substrate preparation are given in the Fig. 5.4.

C. Mother Spawn Preparation Fig. 5.5. Mature master culture | About 300 g prepared substrate (boiled grains mixed with gypsum and chalk) is filled in glucose/milk/glass bottles upto 2/3 volume and plugged with non-absorbent cotton. The plugs are covered with aluminum foil. These bottles are then autoclaved at 22 p.s.i. pressure for 1.5 to 2 h. Autoclaved bottles are left in the room for 24 hours for cooling and are kept on laminar flow under U.V. tube for 20-30 minutes before inoculation. A piece of mycelium (pure culture) grown in Petri plates is aseptically transferred to these bottles and inoculated bottles are incubated (for incubation temperature refer Table 5.1). These bottles are gently shaked on 5th and 10th day for distributing the inoculum evenly in the bottles. This spawn prepared using pure culture mycelium as inocculant is referred as mother spawn (Fig. 5.5). Fully colonized mother spawn bottles can be used for inoculating commercial spawn bags after two to three weeks. |

Commercial spawn can be prepared in polypropylene bags (heat resistant). Normally for half and one kg spawn, the bags should be of 35 x 17.5 cm and 40 x 20 cm in size, respectively. Polypropylene bags should have double sealing at the bottom. After filling the grains a polypropylene neck (height 2 cm, dia. 4 cm) is placed near top by passing polypropylene bag through PP ring and folding back the bag (Fig. 5.6). The bags are plugged with non-absorbent cotton. These are then sterilized at 22 p.s.i. pressure for 1.5 to 2 hours. Autoclaved bags are shaked well before inoculation so that the grains absorb the water droplets accumulated inside the bags. The sterilized bags are kept on the laminar flow under Fig. 5.6. Polypropylene neck U.V. tube for 20-30 minutes. The bags are incubated under aseptic conditions using master spawn as inoculum. Ten to fifteen grams of grains of master spawn are used for inoculating one bag and one bottle of master spawn is sufficient for inoculating 25 to 30 commercial spawn bags. Inoculated bags are again shaked so that the inoculum is well mixed with the grains. The bags are then kept in incubation room for mycelial spread. During incubation, the bags are regularly examined for mould infestation. Contaminated bags should be immediately removed to avoid buildup of contamination in the incubation room. Normally it takes around 15-20 days for complete mycelial run on the grains. Fully colonized bags should thereafter be kept in cold room (40C) for future use (Fig. 5.7). The spawn of button mushroom, Pleurotus can be stored at this temperature. However, neither the culture nor spawn of Volvariella, Ganoderma and Calocybe is stored below 150C (Table 1). The contaminated bottles/ bags/tubes etc. are autoclaved before emptying and discarding. |

Fig. 5.6. Polypropylene neck |

|

Fig. 5.7. Mature spawn

Table 5.1. Temperature requirement for storage and incubation of different mushrooms

| Agaricus | Pleurotus | Lentinula | Volvariella | Calocybe | |

| Days for complete colonization of mother spawn | 20-21 | 8-12 | 20-22 | 6-7 | 15-17 |

| Days for complete colonization in commercial spawn | 12-14 | 8-10 | 15-16 | 5-6 | 12-14 |

| Incubation temperature(°C) during colonization | 25 | 25 | 25 | 32 | 25 |

| Storage temperature (°C) | 4 | 4 | 4 | 15 | 15-16 |

| Shelf life of spawn | Two months | One Month | Three months | <15 days | 15 days |

Whereever possible, freshly prepared spawn should be used since the mycelium is in the state of active growth. The spawn bags after completion of growth can be stored for 2-3 months at low temperature in some cases.

Earlier spawn was prepared in milk or glucose bottles, which was difficult to transport from one place to another. Heat resistant polypropylene bags have revolutionized the spawn industry. High-tech multinational spawn labs now use polypropylene bags with microfilm windows for aeration. Though polypropylene translucent bottles of 5-10 litres capacity are also used in Europe and USA for spawn production, but it has not been introduced in India due to high cost of the material. The mature spawn bags, that is polypropylene bags with grains fully colonized by mycelium should be packed in well ventilated cardboard cartons and stored at 2-4°C. The spawn is transported from one place to another in refrigerated vans or during night when temperature does not rise above 32°C. It is important that spawn bags are not exposed to heat and dust during transport.

F. Liquid SpawnMycelium cultured in liquid medium followed by maceration/ homogenization can also be used for spawning. This is commonly referred as liquid spawn. It can be used for mechanizing inoculation process of spawn multiplication or can be used for inoculating substrates. In one of our experiments shiitake (Lentinula edodes) cultured in liquid medium was used as a liquid spawn for its cultivation on synthetic sawdust substrate. Normal fruit-bodies were harvested from the colonized substrate in 90 days on substrate inoculated with the liquid spawn as compared to 120 days when solid spawn was used.

Strandy cultures showing good growth and not showing fluffy growth, sectoring or slow growth are desirable. During cropping bare patches on bed, deformed fruit bodies with no or few gills, weeping mushrooms indicate degeneration. Multispore cultures degenerate faster than single spore cultures. Hence, it is important to properly maintain the culture at desired temperature and rejuvenate them by change of media and replace them in case of any sign of degeneration.

Spawn production cycle| Step 1 | Select healthy and clean cereal grains | |

| ||

| Step 2 | Boil grains in water (15-20 min.) | |

| ||

| Step 3 | Remove excess water on sieve | |

| ||

| Step 4 | Dry grains in shade (4 h) | |

| ||

| Step 5 | Mix CaCO3 (0.5%) and CaSO4 (2%) on dry wt. basis | |

| ||

| Step 6 | Fill 300 g grains in glucose/milk bottle | |

| ||

| Step 7 | Plug and autoclave at 22 p.s.i. for 1.5 to 2 h | |

| ||

| Step 8 | Inoculate growing mycelium of desired strain using laminar flow | |

| ||

| Step 9 | Incubate in BOD at 23+20C for 20-25 days (shake bottles after 10 days) | |

| ||

| Step 10 | Master spawn is ready |

| Step 1 | Use polypropylene bags instead of bottle | |

| ||

| Step 2 | Upto autoclaving (Step 1 to 7) is same as of mother spawn | |

| ||

| Step 8 | Inoculate with 10-15 grams of mother spawn per PP bags | |

| ||

| Step 9 | Incubate at 23+20C in incubation room (Shake bags after 7-8 days) | |

| ||

| Step 10 | Commercial spawn is ready in 2-3 weeks |

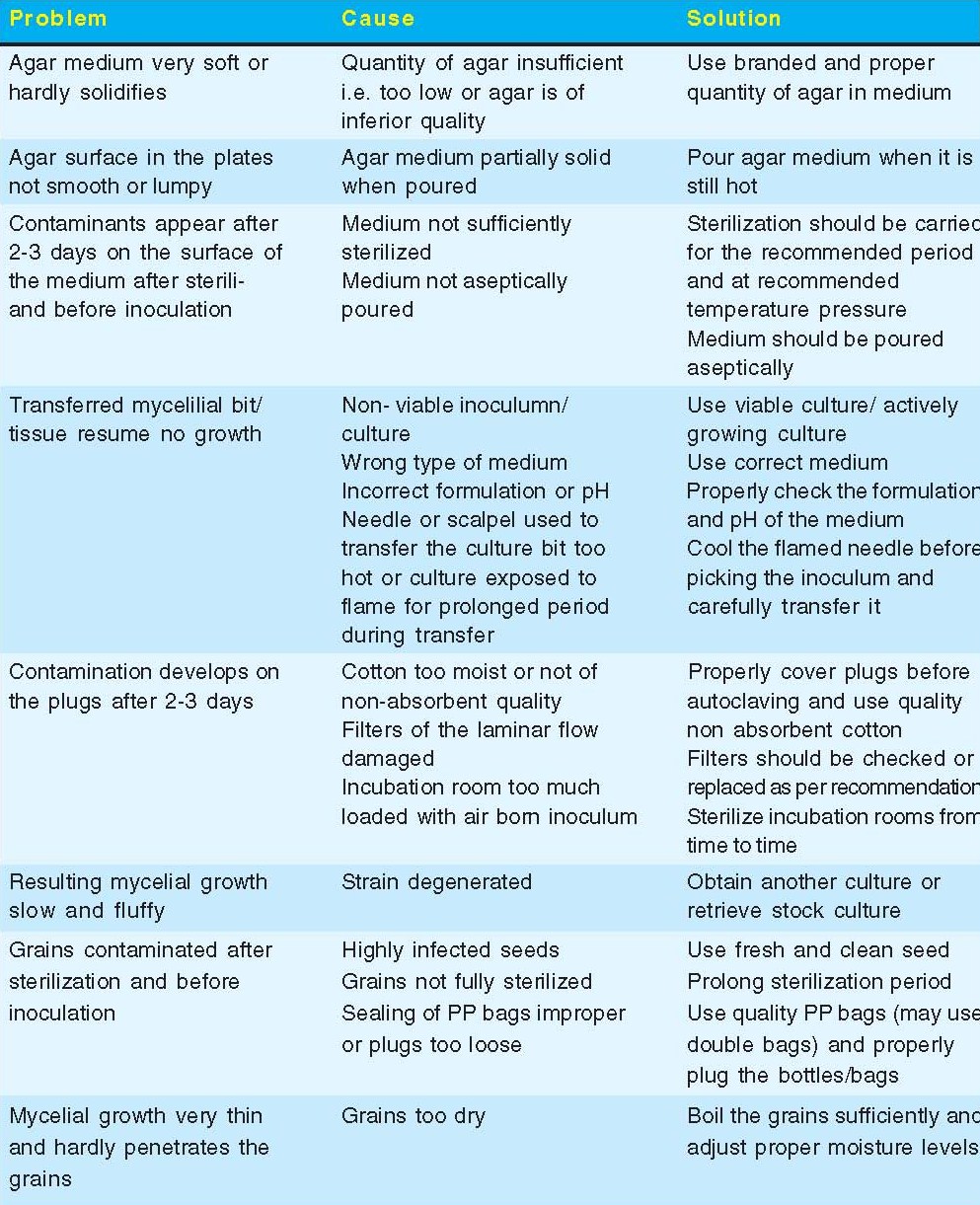

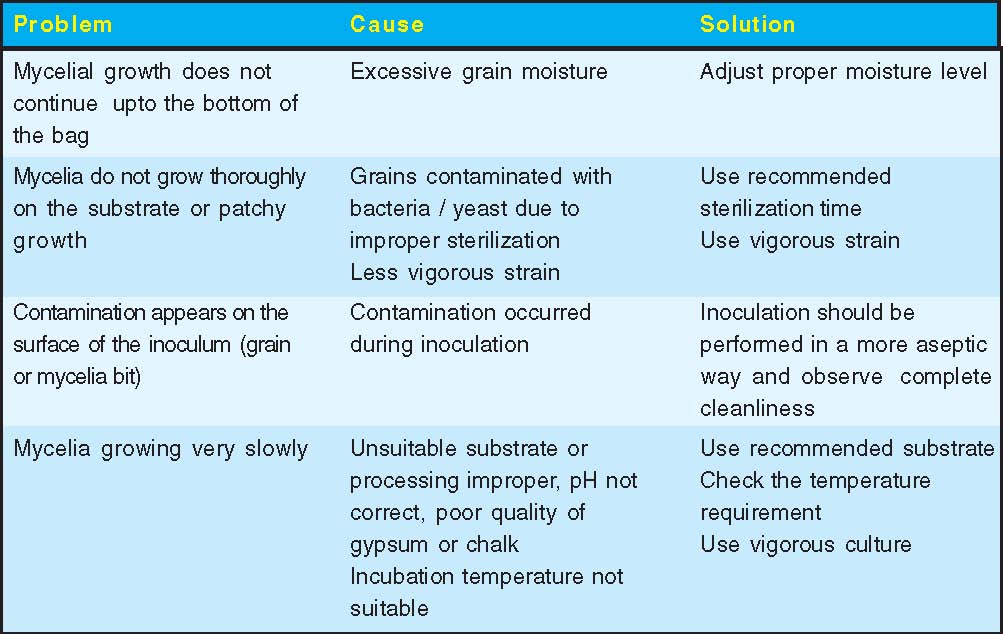

Problems faced during pure culture/ spawn preparation and their solutions are given in Table 5.2.

Table 5.2. Problems, causes and solution during pure culture/ spawn preparation

|

|

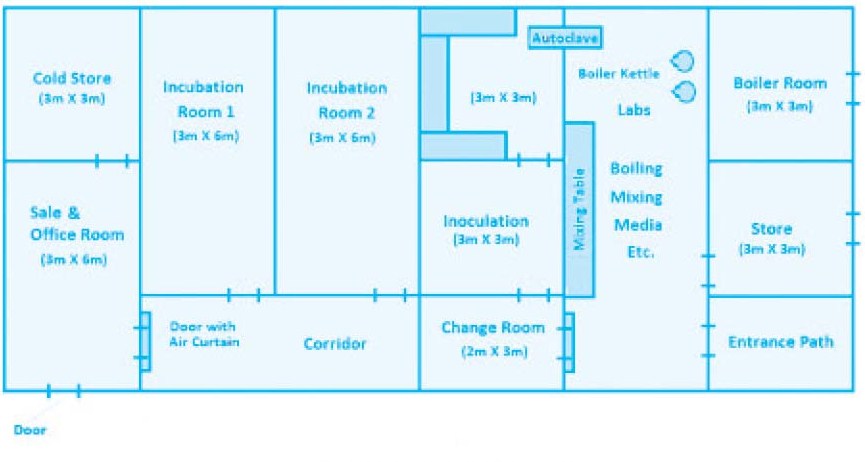

The medium size spawn laboratory (production capacity at least 100 TPA) should have a total built up area of 19 x 8 x 3.6 m (L x B x H). This area will be divided into different work areas like cooking/autoclaving room, inoculation room, and incubation room, washing area, store, office and one cold storage (Fig. 5.8). Cold storage room of 3 x 3 x 3.6 m (L x B x H) is enough to store the spawn at 4-5°C. The walls, roof floor as well as door is provided with heavy insulation (7.5-10 cm thickness) and two air conditioner (each of 1.5 tonnes capacity) are required to maintain temperature inside the room. Two incubation rooms of 3 x 6.0 x 3.6 m (L x B x H) with entire surface area (wall, floor, ceiling, doors) insulated with 5-7.5 cm thick insulation. Two air conditioners (each 1.5 tonnes capacity) are required to maintain temperature (250C) in the incubation room.

|

Fig. 5.8. Layout of Spawn Lab

The equipment required in a spawn laboratory (Fig. 5.9) are:

1. Boiling pans/boiling kettle (vessel) for boiling the grains. Kettle can also be

used if baby boiler is available otherwise kettles working on electricity, kerosene

or gas can be installed. Pans for preparation of medium are also required.

2. Stove or steam line for boiling of wheat grains and preparation of medium.

3. pH meter to check pH of the medium.

4. Autoclave for sterilization of spawn medium and oven for sterilization glassware.

Two electrically operated autoclaves with 100-145 bottle capacity having a dia. of

2 ½' and 3 ¼' height are sufficient. If boiler is available steam operated autoclaves

can be used for better efficiency. A small clinical autoclave can also be kept for

sterilization of culture medium.

5. BOD incubator is needed to incubate cultures and master cultures.

6. Laminar flow cabinet (normally 4 ft. horizontal) is needed for isolation and

multiplication of cultures and spawn inoculation.

|

Fig. 5.9. Equipments for spawn laboratory (a) boiling kettel, (b) autoclave, (c) laminar flow and (d) BOD incubator

7. Refrigerator is needed for short-term preservation of mycelial cultures.

8. Other items like glassware, chemicals for medium preparation, non-absorbent

cotton, polypropylene bags (or bottles), disinfectant (formaldehyde), calcium

carbonate, calcium sulphate are also required.

9. Steel racks in incubation room and cold storage for keeping bags/bottles, exhaust

fans, filters, office table, working tables, troughs, sieves, inoculating needles,

scalpels, test tubes, petri plates etc. are also required.

10. AHUs can be installed for creating positive pressure by filtered air. Similarly air

curtains are desirable to keep aseptic conditions in the lab.

I. Economics

Economics of establishing a spawn laboratory for production and sale of at least 1,00,000 kg spawn per annum is given below:

| 1. | Fixed cost | Cost (Rupees) |

| a | Land procurement and development (300 m2) | Availaible |

| b | Cost of construction: | |

| i) Cost of construction of 152 m2 area @ Rs. 8000/- per m2 | 12,16,000.00 | |

| ii) Cost of insulation of incubation room and cold store | 1,25,000.00 | |

| (250 m2) @ Rs. 500/- m2) | ||

| Total | Rs. 13,41,000.00 | |

| c | Cost of machinery | |

| i) Cost of 4 ACs of 1.5 ton capacity | 2,00,000 | |

| ii) Cost of other equipments | ||

| Autoclave (2 no.) | 8,00,000.00 | |

| Laminar flow | 1,50,000.00 | |

| BOD Incubator | 75,000.00 | |

| Refrigerator | 10,000.00 | |

| pH meter | 5,000.00 | |

| Gas stove | 3,000.00 | |

| Weighing balance | 2,000.00 | |

| Iron racks | 1,00,000.00 | |

| Total | Rs. 11,45,000.00 | |

| 2. | Recurring expenditure | |

| a | Salary | |

| Labour (2 No.) @ Rs. 3000/- month/person | 72,000.00 | |

| Technical Assistant (1 No.) @ Rs. 6000/- month/person | 72,000.00 | |

| Total | Rs. 1,44,000.00 | |

| b | Raw materials | |

| i) Cost of wheat/sorghum/pearl millet grains (600 q) @ | 7,50,000.00 | |

| Rs. 1500/q (Considering 1.8 kg spawn/kg wheat | ||

| and 5-10% contamination) | ||

| ii) Cost of calcium carbonate (3 q) and calcium sulphate (10 q) | 65,000.00 | |

| @ 5000/q | ||

| iii) Cost of non-absorbent cotton 10 q @ Rs. 6500/q | 65,000.00 | |

| iv) Cost of rings | 25,000.00 | |

| v) Cost of 7 quintal of polypropylene bags @ Rs. 6500/q | 4,500.00 | |

| vi) Energy consumption/year | 2,00,000.00 | |

| vii) Miscellaneous (cost of disinfectants, gloves etc.) | 1,00,000.00 | |

| Total | Rs. 12,50.500.00 | |

| Total Recurring Expenditure | Rs. 13,94,500.00 | |

| 3. | Interest and Depreciation | |

| 1. On Building (Rs.13,41,000) (5% depreciation and | 2,27,970.00 | |

| Interest @ 12% ) | ||

| 2. On machinery (Rs.11,45,000.00) | 2,51,900.00 | |

| (10% depreciation and 12% Interest) | ||

| Total | Rs. 4,79,870.00 | |

| 4. | Cost of production and return | |

| a | Raw materials | 12,50,500.00 |

| b | Wages and salary | 1,44,000.00 |

| c | Interest and depriciation | 4,79,870.00 |

| Total | Rs.18,74,370.00 | |

| 5. | Return | |

| a | Income from sale of 1 lakh spawn bags @ Rs. 50/kg | 50,00,000.00 |

| Net profit per year Rs. (50,00,000 -18,74,370) = | Rs. 31,25,630.00 |

No spawn standards as such have been set out in our country. However based on the research the following standards appears reasonable.

Pure culture can be equated to nucleus seed, master spawn to breeder seed and commercial spawn to foundation seed.

1. Pure culture (Nucleus seed)

a The culture should be genetically pure and true to type.

b Culture should be obtained from Research organization or authentic source.

c Free from any kind of fungal and viral contamination.

d Culture should be maintained on compost extract agar medium.

e Culture should indicate specific growth rate on defined medium and at defined

temperature.

f Visually the culture should be strandy and off white in colour in Agaricus, pure

white and thick fluffy growth in Pleurotus, cottony fluffy with brown sclerotia

(after 12-15 days) in Volvariella, pure white, dense, thick and fluffy growth in

Calocybe indica and pure white later on turning to light brown pigmentation in

Lentinula edodes.

g Culture should be stored at 4-60C for Agaricus, Pleurotus and Lentinula and

between 18-220C in Volvariella and Calocybe indica.

h The incubation temperature should be between 32±2°C for Volvariella and

Calocybe indica and 250C for Agaricus, Pleurotus and Lentinula.

a Breeder seed should always be prepared from pure culture.

b Free from any kind of contamination.

c It should be multiplied on wheat, jowar, bajra or barley grains.

d Breeder seed should be incubated at 25±20C for Agaricus, Pleurotus, Lentinula

and 32±20C for Calocybe indica and Volvariella.

e The master spawn should be stored at 4-60C for 40-45 days in Agaricus,

Pleurotus, Lentinula and 18-200C days in Calocybe indica and Volvariella for

maximum 30-40 days.

f It should be produced in autoclavable transparent glass bottles

a The incubation temperature should be 25±20C for Agaricus, Pluerotus,

Lentinula and 32±20C for Volvariella and Calocybe indica.

b Spawn should always be prepared from master spawn (Breeder seed).

c Free from any kind of contamination.

d It should be multiplied on wheat, jowar, bajra or barley grains.

e Spawn should not be older than 60 days in Agaricus, 30-45 days in Pleurotus,

Lentinula and 30-40 days in Calocybe indica and Volvariella.

f Certified spawn should be stored at 4-60C in Agaricus, Pleurotus and Lentinula

and 18-200C in Calocybe indica and Volvariella.

g The bag should indicate lot no., date of inoculation, variety/strain and quantity.

h For every new lot of commercial seed (foundation seed), fresh master spawn

(breeder seed) should be used. Commercial spawn may not be used for further

multiplication of seeds as it may lead to higher contamination and decline in

yield.